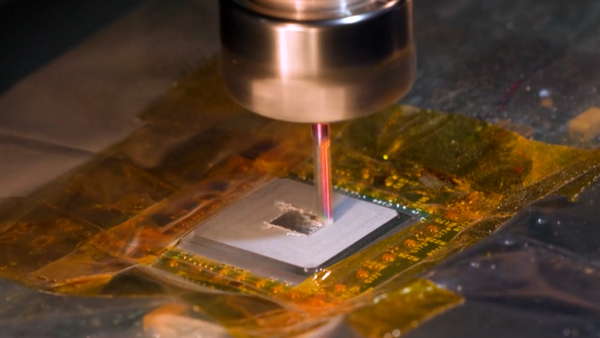

Precision removal of underfilled BGA components using CNC milling systems. Ensures compliance with IPC-7711/7721 for high-reliability circuit board rework and repair.

Our BGA Reballing delivers fast, precise, IPC and JEDEC-compliant rework for lead-free to leaded conversions. With advanced equipment, expert staff, and rigorous inspection, we ensure top-tier quality, reliability, and repeatable results.

Trusted worldwide for precision BGA rework, we deliver IPC-compliant solutions for removal, reballing, pad repair, X-ray inspection, and circuit modification—backed by advanced systems and unmatched technical expertise.

BGA site modification using thin copper ribbon conductors—engineered for tight spacing under BGA components where standard jumper wires won't fit. Trusted, expert-level rework performed by the industry’s most experienced technicians.

Trusted experts in high-precision circuit board modifications, we specialize in jumper wire installation, trace isolation, and complex ECO rework. Our skilled technicians ensure accurate, reliable results for the most complex modifications.

We deliver expert-level rework services for surface-mount, BGA, and through-hole components, using advanced equipment and IPC-trained technicians. We provide reliable solutions for the most complex challenges.

Restore damaged or worn gold edge contacts with our IPC-recommended brush plating process. We deliver precise, durable, like-new finishes that ensure full conductivity, meet specs, and extend the performance life of your circuit boards.

Circuit Technology Center and Keysight Technologies deliver a complete turn-key solution for testing DIMMs directly at BGA sites using W2630A series probes—enabling high-performance memory analysis with expert installation support.

Fast, flexible tape and reel services for SMT, through-hole, and custom components. EIA-481 compliant processing with inspection, ESD protection, MSL dry bake, and packaging per J-STD-033 and J-STD-020 standards.

Automated component tinning using six robotic hot solder dip (RHSD) systems for finish conversion and gold mitigation. Fully compliant with GEIA-STD-0006 and J-STD-001, with leaded and lead-free processing.

We provide trim and form services for SMT and through-hole components. Custom tooling, MSL baking, JEDEC packaging, and post-process RHSD tinning ensure readiness for assembly and compliance with industry standards.

We use the advanced Dage Quadra 7 system for X-ray inspection to support BGA rework and fault analysis. High-resolution imaging, oblique views, and IPC-A-610 certified visual inspection ensure exceptional quality and defect detection.