Circuit Technology Center is a globally recognized leader in BGA rework, trusted by top companies in aerospace, defense, and electronics manufacturing. Our services range from individual assemblies to full production lots, offering unmatched precision and consistency. Every project is performed to strict IPC standards using advanced rework systems and proven methods. From BGA removal and replacement to pad restoration and reballing, our experienced team ensures the highest levels of reliability and repeatability. We deliver solutions that meet the most demanding quality and performance requirements.

Key Highlights

- Globally recognized authority in BGA rework

- Trusted by aerospace, defense, and electronics leaders

- Seven advanced BGA rework systems

- IPC-compliant processes for every project

- Skilled engineers and technicians with high-reliability expertise

- Comprehensive inspection, including high-resolution X-ray

- Proprietary flat conductor method for BGA site modifications

- Proven results for both small-scale and high-volume needs

Technical Specifications

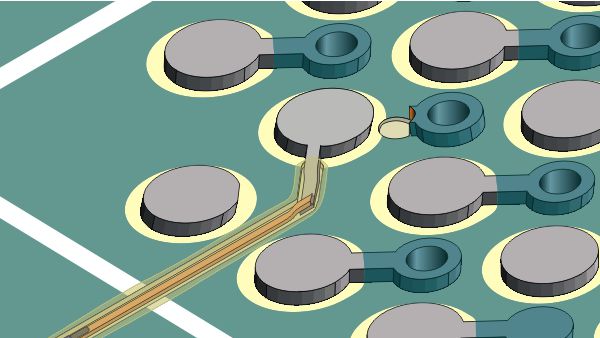

- Precision BGA removal, replacement, and salvage

- High-resolution X-ray inspection and analysis

- Circuit pattern modification at BGA sites

- Repair of lifted or missing BGA pads

- Restoration of solder mask at BGA locations

- BGA reballing with leaded or lead-free solder

- Thermally bonded, adhesive-backed pad restoration

- Proprietary ultra-thin copper ribbon for circuit modifications

Compliance / References

- 9.1.1 BGA Component Rework Process Flow

- 9.2.1 BGA Component Rework Profile Development, Standard Method

- 9.2.2 BGA Component Rework Profile Development, Smart Track Method

- 9.3.1 BGA Component Rework

- IPC 7711/7721 Rework, Modification, and Repair of Electronic Assemblies

- IPC-A-610 Acceptability of Electronic Assemblies

- IPC-J-STD-001 Requirements for Soldered Electrical and Electronic Assemblies

- IPC-J-STD-002 Solderability Tests for Component Leads, terminations, Lugs, Terminals and Wires

- IPC-J-STD-004 Requirement for Soldering Fluxes

- IPC J-STD-006 Requirements for Electronic Grade Solder Alloys and Fluxed and Non-Fluxed Solid Solders for Electronic Soldering Applications

- IPC-JEDEC-J-STD-020 Moisture/Reflow Sensitivity Classification for Nonhermetic Surface Mount Devices

- IPC-JEDEC-J-STD-033 Handling, Packing, Shipping and Use of Moisture, Reflow, and Process Sensitive Devices

- IPC-7095 Design and Assembly Process Implementation for BGAs

- IPC-7525 Stencil Design Guidelines (Solder Paste)

- JESD22-B101 External Visual Standard

- JESD625C.01 Requirements for Handling Electrostatic-Discharge-Sensitive (ESDS) Devices