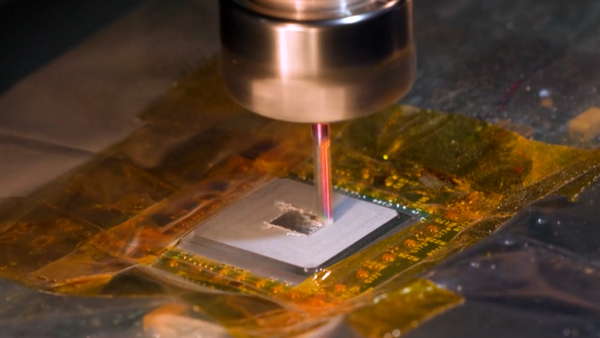

Removing BGA components that have underfill presents unique challenges due to the mechanical bond formed between the device and the circuit board. Specialized CNC milling systems are used to mill away the component and underfill without causing damage or degradation to the circuit board surface and adjacent components. Circuit Technology Center technicians follow proven methods and use advanced state-of-the-art tools to ensure clean, damage-free removal.

Key Highlights

- Globally recognized authority in BGA rework

- Trusted by aerospace, defense, and electronics leaders

- Many advanced BGA rework systems

- IPC-compliant processes for every project

- Skilled engineers and technicians with high-reliability expertise

- Comprehensive inspection, including high-resolution X-ray

- Proven results for both small-scale and high-volume needs

Technical Specifications

- Precision BGA removal, replacement, and salvage

- High-resolution X-ray inspection and analysis

Compliance / References

- 9.5.1 BGA Component Removal, Machining Method

- IPC 7711/7721 Rework, Modification, and Repair of Electronic Assemblies

- IPC-A-610 Acceptability of Electronic Assemblies

- IPC J-STD-006 Requirements for Electronic Grade Solder Alloys and Fluxed and Non-Fluxed Solid Solders for Electronic Soldering Applications

- IPC-JEDEC-J-STD-020 Moisture/Reflow Sensitivity Classification for Nonhermetic Surface Mount Devices

- IPC-JEDEC-J-STD-033 Handling, Packing, Shipping and Use of Moisture, Reflow, and Process Sensitive Devices

- IPC-7095 Design and Assembly Process Implementation for BGAs

- JESD22-B101-External Visual Standard

- JESD625C.01 Requirements for Handling Electrostatic-Discharge-Sensitive (ESDS) Devices