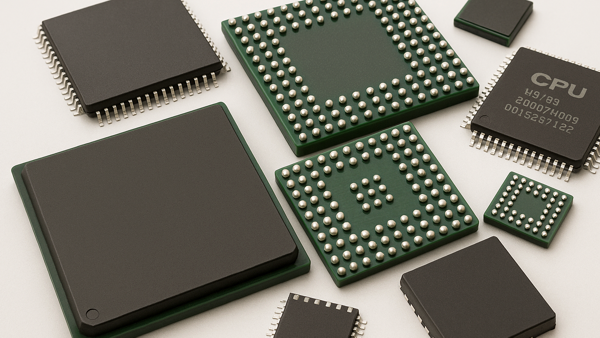

Circuit Technology Center offers advanced component tinning services using fully programmable Robotic Hot Solder Dip (RHSD) systems for precise and repeatable results. Whether mitigating tin whiskers by converting from lead-free to tin-lead or removing gold plating to ensure solder joint reliability, our processes are tightly controlled for depth, angle, dwell time, and temperature. All services are performed to GEIA-STD-0006 and J-STD-001 standards, ensuring 100% finish replacement and consistent solderability. With segregated lead-free equipment, comprehensive inspection, and flexible packaging options, we deliver industry-compliant solutions tailored to your requirements.

Key Highlights

- Six fully programmable Robotic Hot Solder Dip systems with precise process control

- Complete compliance with GEIA-STD-0006 and J-STD-001 standards

- Guaranteed 100% finish replacement, including gold removal

- Segregated equipment for RoHS-compliant tinning

- Pre- and post-process inspections with batch cleaning and MSL baking

- Flexible packaging in JEDEC trays, waffle packs, or tape and reel

- In-house testing capabilities for solderability, alloy composition, and cleanliness

- Over four decades of expertise in high-reliability component services

Technical Specifications

- Lead-free to tin-lead (Sn63/Pb37) conversion for tin whisker mitigation

- Gold and oxidation removal with full finish replacement

- Batch cleaning and MSL bake-out per J-STD-033

- Testing capabilities:

* Ionic cleanliness (ROSE) per IPC-TM-650-2.3.25

* XRF alloy composition and thickness per JESD 213

* Solderability per J-STD-002

* Visual inspection

* SAM testing per J-STD-035

* Destructive physical analysis (DPA) per MIL-STD-1580

* Hermeticity testing per MIL-STD-883

* Temperature, humidity, and bias testing

* Parametric testing - Component reballing and tinning for BGAs, LGAs, QFPs, PLCCs, SOICs, SOT-23s, through-hole connectors, and discrete SMT devices

- Packaging and marking services:

* Tape and reel per EIA-481

* MSL dry bake per J-STD-033

* MSL packaging per J-STD-020

Compliance / References

- 11.0 Component Lead, Pin, Pad, and Termination Conditioning and Tinning

- 11.2 Component Termination Conditioning and Tinning, Chip/Discrete Components

- 11.3 Component Lead Conditioning and Tinning, Radial Lead Components

- 11.4 Component Lead Conditioning and Tinning, Axial Lead Components

- 11.5 Component Lead Conditioning and Tinning, J-Lead Components

- 11.6 Component Lead Conditioning and Tinning, Gull Wing Components

- 11.7 Component Pad Conditioning and Tinning, Leadless Components

- 11.8 Component Pin Conditioning and Tinning, Connectors, Through-Hole

- GEIA-STD-0006 Requirements for Using Robotic Hot Solder Dip to Replace the Finish on Electronic Piece Parts

- IPC-J-STD-001 Requirements for Soldered Electrical and Electronic Assemblies

- IPC-J-STD-004 Requirement for Soldering Fluxes

- IPC J-STD-006 Requirements for Electronic Grade Solder Alloys and Fluxed and Non-Fluxed Solid Solders for Electronic Soldering Applications

- IPC-JEDEC-J-STD-020 Moisture/Reflow Sensitivity Classification for Nonhermetic Surface Mount Devices

- IPC-JEDEC-J-STD-033 Handling, Packing, Shipping and Use of Moisture, Reflow, and Process Sensitive Devices

- JESD22-B101 External Visual Standard

- JESD625C.01 Requirements for Handling Electrostatic-Discharge-Sensitive (ESDS) Devices

- MIL-PRF-38535 Performance Specification Circuits (Microcircuits) Manufacturing, General Specification

- MIL-STD-202 Test Method Standard Electronic and Electrical Component Parts

- MIL-STD-883 Department of Defense Test Method Standard Microcircuits