Replacing a 150-pin connector on a tight deadline? A solder fountain enables fast, simultaneous pin reflow—far faster than hand desoldering. With prep, skill, and care, it's quick, safe, and reliable.

Microscopes are vital for precision rework as components shrink. Stereo zoom models with ergonomic design, adjustable lighting, and ESD safety help technicians stay comfortable and deliver high-quality work.

Faced with a shorted 2600-ball BGA, precision is key. With expert removal, careful paste application, thermocouple monitoring, and smart safeguards, this challenging rework passed x-ray with flying colors.

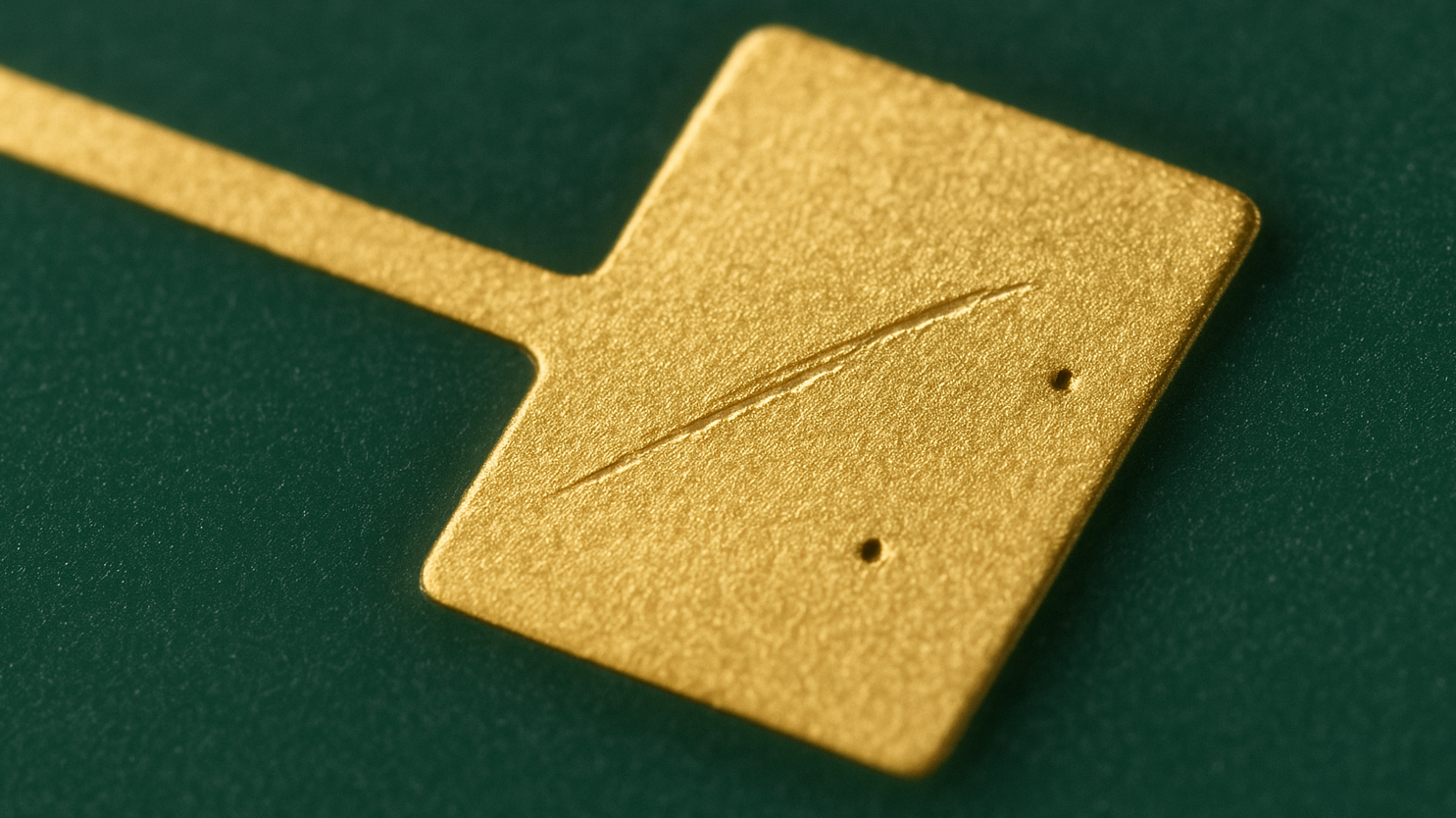

Modifying conductor widths on high-frequency PCBs demands surgical precision. In this case, a custom blade mounted in a milling machine allowed controlled pad removal—protecting the board from deeper damage.

Faced with deep gold pad voids on a massive, costly backplane, standard fixes failed. Using conductive paste, precision application, and selective plating, we restored pad integrity.

Scraping valuable boards due to base material damage is avoidable. Using epoxy fills, edge transplants, or key-slot repairs, even large, costly boards can be reliably restored and returned to service.

Unwanted solder mask on a pad or footprint? Don’t panic. Whether by scraping, milling, stripping, or microblasting, skilled techs can safely remove it—each method chosen based on control, location, and board type.

When 10 internal ground vias were missing on a finished board, the through-board wire method from IPC 4.2.5 saved the day. With micro-drilling, precision soldering, and epoxy sealing, full connectivity was restored.

BGA rework demands precision, experience, and specialized skill. The right operator - not just the right machine - determines success, ensuring accuracy, board stability, and reliable inspection results.

A damaged PGA pin was restored using a machined replacement pin, high-temperature solder, precise fixturing, and epoxy reinforcement - saving a valuable component.

A 676-ball BGA redesign revealed 23 misrouted connections. The fix? Precision rerouting from center pads to new perimeter pads using foil jumpers, pad replacements, and expert trace routing—restoring full functionality.

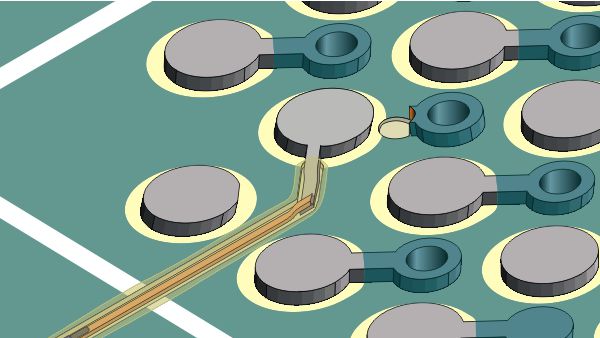

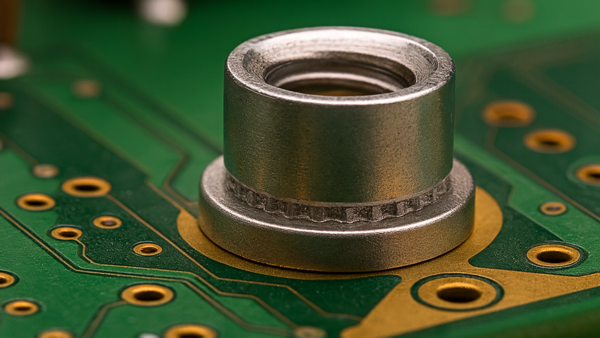

Press-in fastener errors can cause serious board damage. Circuit Technology Center repairs include precision milling, epoxy fill, and eyelet insertion to restore structural and electrical integrity.

Benchtop hot air tools are ideal for manual component removal, but success hinges on proper nozzle choice, precise board positioning, and careful prep. With skill and control, even tough removals can be done safely.

When a high-density circuit board lost multiple USB-C pads due to connector damage, our team successfully restored full functionality using precision adhesive-backed pad replacements and thermal bonding techniques.

This blog outlines best practices for adding jumper wires to circuit boards, covering placement, routing, insulation, and stress relief to ensure reliability and reworkability.

Edge milling can correct circuit board thickness issues post-assembly, requiring precision equipment, proper fixturing, and skilled operators to meet tight tolerances and ensure board functionality.

Converting a soldered BGA to a socketed one often requires gold plating 1000+ pads. Using conductive ink to link vias, we plated all pads cleanly—prep and cleanup took longer than plating itself!

A reversed trace issue on 18-layer boards was fixed using milling, X-ray, and copper ribbon crossover. Precision rework and epoxy fill left results that impressed even the OEM.

A circuit board design error prompted two rework methods: jumper wires for fully assembled boards and surface ribbon conductors with epoxy insulation for partially assembled boards, ensuring circuit integrity and efficiency.

Despite advances in automation, hand soldering remains essential and highly skill-dependent. Proven techniques—such as controlled fine-pitch soldering, auxiliary heat desoldering, and BGA pad masking—ensure reliable, repeatable, and low-stress results.

Component salvaging combats e-waste by extending component lifecycles, conserving raw materials, and easing supply chain strain.

Damaged or contaminated gold edge contacts can be repaired by replating or replacing them. Replating suits high-volume jobs, while replacement is more suitable for smaller-scale fixes. Both methods restore reliability and performance.

A missing ground plane caused circuit failure in thousands of boards. Initial wire rework was rejected, so technicians created a precise, hidden repair by milling, micro-soldering, and epoxy-filling for an invisible fix.

Technicians undertook a complex rework of potted LED circuit boards by precisely removing silicone gel to access and replace faulty 44-pin QFPs, ensuring reliable results with advanced hot gas systems and expert soldering techniques.

Upgrading to a Dage X-ray system transformed inspections, revealing clearer, angled views of voids and BGAs. With precise measurements and distortion-free zoom, it outperforms older 2D machines in every way.

This BGA site modification is a complex process that uses flat ribbon circuits, eliminating the need for thick jumper wires. The process requires high skill, specialized tools, and experience to perform reliably.

Circuit Technology Center and Keysight now offer a turnkey solution for testing DIMMs at BGA sites using Keysight’s DDR2 BGA probes. Skilled rework, precise reballing, and X-ray inspection are essential.

This extra-strength repair process corrects damaged ejector handle mounting holes by installing epoxy-coated dowel plugs, ensuring structural integrity under stress typical of standard circuit board use.

Rework often demands custom tooling. Circuit Technology Center created a custom .020 inch hole saw by modifying a carbide end mill to isolate a pad from ground, proving in-house tool adaptation is essential.

Omitting a solder mask at a BGA site during PCB prototyping causes solder bleed and defects. To fix it, reapply solder mask manually with precision tools, ensuring pad isolation and circuit integrity.

A military contractor faced missing SMT pads, which are critical for capacitor placement. Using precision milling, dry-film epoxy-backed pads were bonded and lap-soldered, thereby restoring functionality without the need for surface wires.

Secondary reflow often fails to fix open solder joints caused by pad oxidation. Reliable rework requires component removal, pad conditioning, and retinning to prevent damage from repeated heat cycles.

Technicians corrected a signal error by isolating a via from layer nine and reconnecting it to layer 15 using micro-surgery techniques, precision milling, and epoxy sealing—expert work done right.

Large BGA components can warp during rework, resulting in solder bridging at the corners. Technicians prevent shorts by placing heat-resistant spacers under the corners, thereby stabilizing the alignment during reflow.

A high-reliability board failed in the field due to incomplete solder fill in thick through-holes. Technicians identified underfilled barrels via X-ray and reworked them using controlled heat and vacuum tools.

Component salvage can recover value from non-functional circuit boards, but success hinges on careful evaluation of coating, moisture, ESD sensitivity, heat tolerance, and packaging to ensure reusability.

Even severe handling damage to circuit boards—like cracks or edge dings—can be repaired using trusted epoxy-based methods. Following approved procedures restores structural integrity and usability.

Backplanes were built with 24 unplated holes—no internal layer connections. We milled from the top side to access inner layers, soldered copper ribbon jumpers, tested continuity, and sealed with epoxy.

Damaged solder mask at a BGA site can cause solder to flow off the pad, leading to weak or open joints. Skilled rework techs must inspect, repair missing solder mask with epoxy, and bake properly before BGA replacement begins.

A critical misrouting error nearly caused sparks to fly—literally. With time too tight for a redesign, 256 precision-placed jumper wires fixed the issue, saving the project and avoiding costly delays.

When standard methods fall short, custom rework solutions are essential. This case details a certified repair for large ground plane voids using adhesive-backed copper disks and precision bonding techniques.

Successful BGA rework demands technician expertise, proper tools, thermal profiling, and thorough preparation. Avoiding six key mistakes minimizes damage, ensures reliability, and boosts process yields.

For an invisible conductor repair, replace the damaged section with a tinned flat copper ribbon. Circuit Tracks match the original size and shape, ensuring a clean, secure, and professional-looking fix.

A full row of plated holes wasn’t grounded as required. Technicians milled a groove, exposed layer 3, and soldered a copper bus under each pad—no surface wires. Reliable, clean, and epoxy-sealed.

Modifying circuit boards can get creative—stacked or flipped parts aren't unusual. Done right, these tweaks meet IPC standards. Just follow key rules to ensure safety, clarity, and mechanical stability.

When a BGA didn't match the board footprint, we built an 8-layer daughter card to bridge the gap. It added components, used high-temp solder, and ensured a clean, reliable fix—no re-spin needed.

Facing component shortages, companies are turning to salvage. Circuit Technology Center safely removes, reballs, retins, and repackages parts—even BGAs—following strict IPC and ESD protocols.

Drilling thick, multi-layer boards post-production is tough—especially when internal planes are close. Oblique X-ray inspection revealed hidden fibrous debris causing shorts, enabling a precise, successful repair.

Removing 170-pin connectors without damaging the jumpers or the board required serious preparation. Heat shields and high-temp tape protected sensitive areas, while a solder fountain ensured clean removal and installation.

Using vias in BGA pads saves space, but can backfire. Voids in fill materials caused warping and blowouts during rework. One BGA ball even burst, ejecting solder—proof that voids and heat don't mix.

Reliable circuit board repair depends on conformance level—how closely a fix matches the original design. IPC standards guide this, but skill, tools, and judgment play a huge role in lasting results.

Through-hole boards are still common and often need plated hole repair. Procedure 5.1 can be helpful, but selecting the right eyelet is crucial. Follow the selection criteria to ensure a reliable fix.

When 100 circuit boards needed urgent BGA rework, a skilled team rerouted circuits by removing pads, bonding new ones, and adding copper tracks and jumper wires—saving time, money, and the entire batch.

Soldering gold connector pins can be tricky—especially during rework. By combining mini-wave removal, vacuum desoldering, and solder donuts, technicians achieved reliable results despite the tough constraints.

When a broken SD card held priceless White House photos, Circuit Technology Center saved the day—swapping chips into a donor card to recover every image. Crisis averted with steady hands and smart repair.

Cutting circuits—both surface and internal—is precise, high-stakes work. Whether severing shorts or correcting design flaws, skilled techs use drills, X-rays, and microscopes to cut cleanly and avoid collateral damage.

Instead of messy dead-bugging, technicians bonded precision copper foil patterns to add 16 components cleanly. The result? Fewer jumper wires, faster assembly, and a reliable fix ready for reflow.

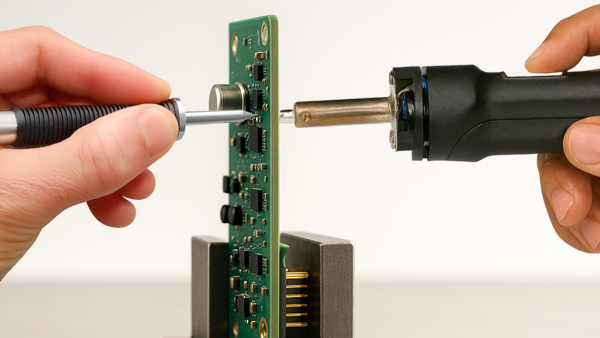

Solder fountains simplify rework for large through-hole parts but demand care. They deliver intense heat fast—great for speed, risky for damage. Safety, prep, and precision are key to successful use.

Pad-to-part mismatches can derail assembly. IPC specs offer guidance, but fixes aren't always simple. In this case, 60+ custom pads were bonded using the film adhesive method—restoring function and reliability.

Solder on gold edge contacts? It’s serious—but fixable. We remove the solder, then re-plate the contacts using chemical and electroplating steps. With care and compliance, costly assemblies can be saved.

Cosmetic circuit board repairs, like fixing burns or holes, are vital for reliability and appearance. Using micro-drills, epoxy, and color matching restores integrity and meets quality standards.

BGA rework blends precision with artistry, especially in solder paste application. Traditional mini-stencils remain common but imperfect. Newer methods—ball-side stenciling and flexible polymer stencils—offer better consistency.

Dale Granger-Eckert retires after 31+ years as a standout technician at Circuit Technology Center. She pioneered key repair methods, mentored many, and leaves behind a legacy of skill, heart, and excellence.