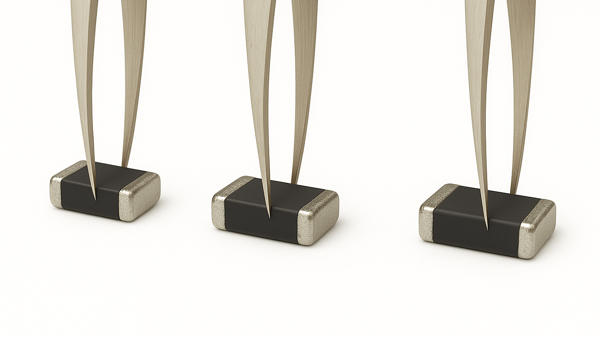

Circuit Technology Center offers precision tinning services for surface-mount discrete components, including capacitors and resistors in 0603 sizes and larger, utilizing fully automated Robotic Hot Solder Dip (RHSD) systems. This service is primarily used to convert lead-free terminations to tin-lead (Sn63/Pb37) to mitigate tin whisker growth and to remove gold plating from leads to meet gold mitigation requirements.

Our RHSD equipment features fully programmable control over dip depth, dwell time, and solder temperature, enabling consistent, repeatable results in full compliance with GEIA-0006 standards. This controlled process ensures complete removal and replacement of the original finish with Sn63/Pb37 solder.

Gold plating removal is performed in strict accordance with J-STD-001 standards. Post-process services include batch cleaning, MSL baking and dry packaging, tape-and-reel packaging, and both pre- and post-process electrical and visual inspections, as required.

Additional Component Modification Services and More Information

- BGA Component Reballing Services

- LGA Component Tinning

- QFP Component Tinning

- PLCC Component Tinning

- SOIC Component Tinning

- SOT-23 Component Tinning

- Through-Hole Connector Tinning

In-house post-processing testing capabilities include:

- Ionic cleanliness (ROSE) testing per IPC-TM-650-2.3.25

- XRF for alloy composition and finish thickness per JESD 213

- Solderability testing per J-STD-002

- Visual inspection

Other available testing services include:

- SAM (scanning acoustic microscopy) testing per J-STD-035

- Destructive physical analysis (DPA) per MIL-STD-1580

- Hermeticity testing (fine and gross leak) per MIL-STD-883

- Temperature, humidity and bias testing

- Parametric testing

Component Marking and Packaging Services include: