|

Outline

This procedure outlines the inspection method and pass/fail criteria to be used during the final inspection of BGA Component Deballing and Reballing to ensure compliance with Work Order requirements.

|

|||||||||||||||||||||||||||||||||||||||||||||||

|

Procedure

Moisture Sensitive Device Control

Reballing Inspection Procedure

Disposition of Rejected Components |

|||||||||||||||||||||||||||||||||||||||||||||||

Images and Figures

BGA Component Reball Inspection

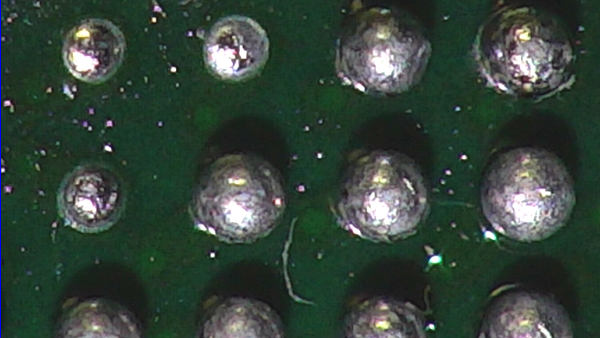

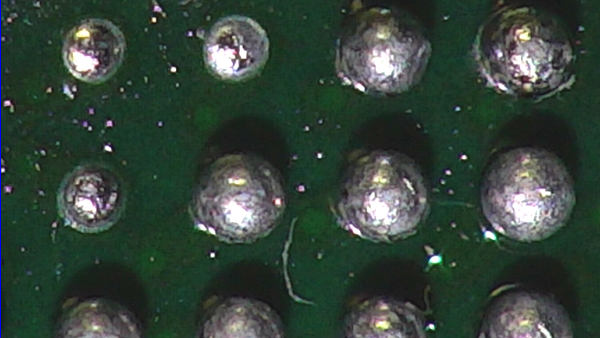

Figure 1. Crushed solder spheres. This is a reject condition.

Figure 2. Excessive flux and oxidation. This is a reject condition.

Figure 3. Substrate damage. This is a reject condition.

Figure 4. Missing solder spheres. This is a reject condition.

|

|||||||||||||||||||||||||||||||||||||||||||||||

9.1.3 BGA Component Reball Inspection

Procedure covers guidelines for inspection of reballed BGA components.

Minimum Skill Level: Expert

Conformance Level: High

REQUEST FOR QUOTE GUIDES INDEX

BGA Component Reball Inspection

Crushed solder spheres. This is a reject condition.

Excessive flux and oxidation. This is a reject condition.

Substrate damage. This is a reject condition.

Missing solder spheres. This is a reject condition.

For help with BGA rework, contact the globally recognized authority, trusted by aerospace, defense, and electronics manufacturers.

LEARN MORE

SLIDESHOW STARTING

❮

❯