|

Outline

This procedure covers one commonly used method for removing surface mount chip components.

|

|||||||||||||||||||||||||||

|

Procedure

Note: Determine the direction the part is to be swept off the circuit board surface. Densely packed circuit board assemblies often leave only one direction for the rework tool to follow when sweeping the part off the surface

|

|||||||||||||||||||||||||||

Images and Figures

Component Removal, Surface Mount Chip Components, Hot Tweezer Method

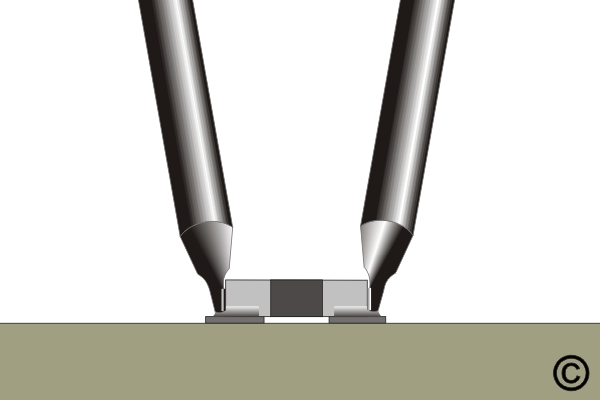

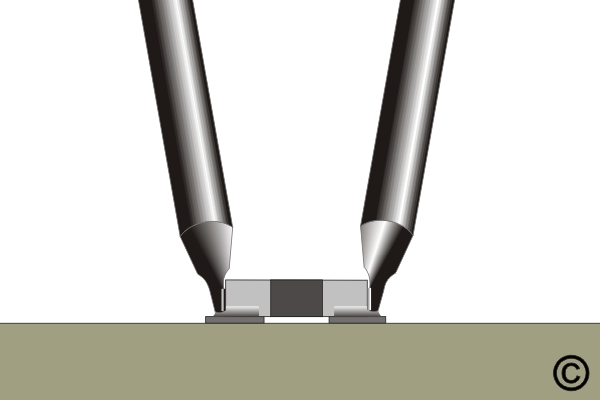

Figure 1. Place the tweezer tips in position. When the solder melts, lift the component off the circuit board

|

|||||||||||||||||||||||||||

8.2.2 Component Removal, Surface Mount Chip Components, Hot Tweezer Method

Procedure covers removal of surface mount chip components on circuit board assemblies using a hot tweezer method.

Minimum Skill Level: Intermediate

Conformance Level: High

REQUEST FOR QUOTE GUIDES INDEX

Component Removal, Surface Mount Chip Components, Hot Tweezer Method

Place the tweezer tips in position. When the solder melts, lift the component off the circuit board

Do you need help with surface mount and through-hole component rework or salvage?

LEARN MORE

SLIDESHOW STARTING

❮

❯