|

Outline

This procedure covers one commonly used method for removing surface mount chip components.

|

|||||||||||||||||||||||||||

|

Procedure

Tip Preparation

The solder provides surface tension to lift the component off the pads after reflow. Since the tip has more metal surface area than the pads on the circuit board, the solder will be drawn toward the metal tip, and so will the component.

|

|||||||||||||||||||||||||||

Images and Figures

Component Removal, Surface Mount Chip Components, Forked Tip Method

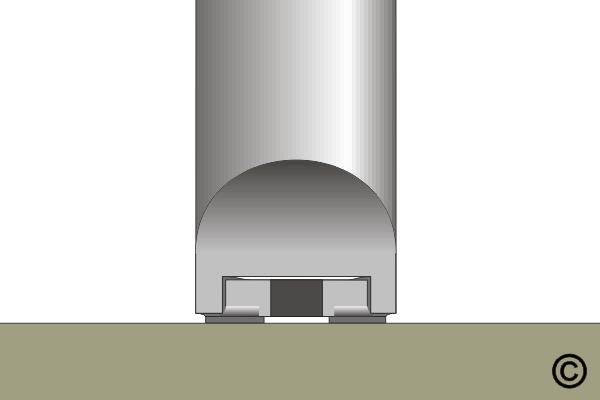

Figure 1. Forked tip shown with solder added to cavity to enhance removal operation.

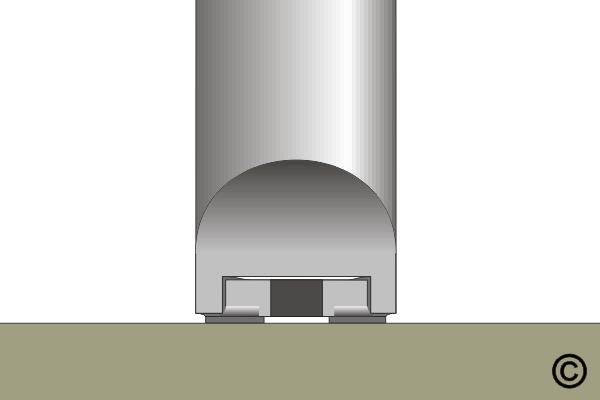

Figure 2. Removing SMT chip component with forked tip. After solder has melted lift tip out and up.

|

|||||||||||||||||||||||||||

8.2.1 Component Removal, Surface Mount Chip Components, Forked Tip Method

Procedure covers removal of surface mount chip components on circuit board assemblies using a forked tip method.

Minimum Skill Level: Intermediate

Conformance Level: High

REQUEST FOR QUOTE GUIDES INDEX

Component Removal, Surface Mount Chip Components, Forked Tip Method

Forked tip shown with solder added to cavity to enhance removal operation.

Removing SMT chip component with forked tip. After solder has melted lift tip out and up.

Do you need help with surface mount and through-hole component rework or salvage?

LEARN MORE

SLIDESHOW STARTING

❮

❯