6.2.1 Jumper Wires, BGA Components, Circuit Track Method

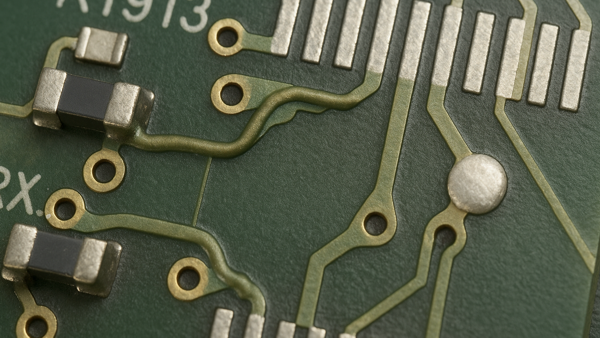

Procedure covers methods for using circuit tracks at BGA locations on circuit board assemblies.

Minimum Skill Level: Expert

Conformance Level: Medium

REQUEST FOR QUOTE GUIDES INDEX

Jumper Wires, BGA Components, Circuit Track Method

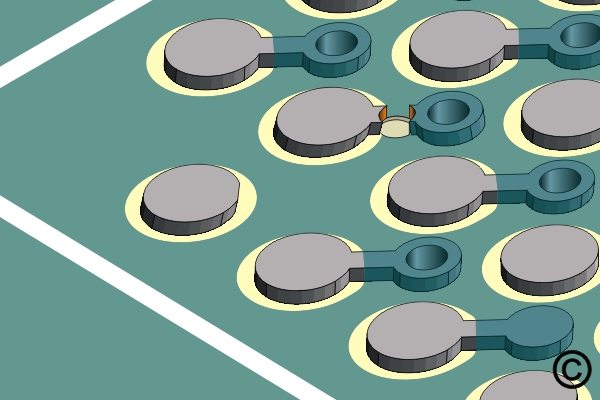

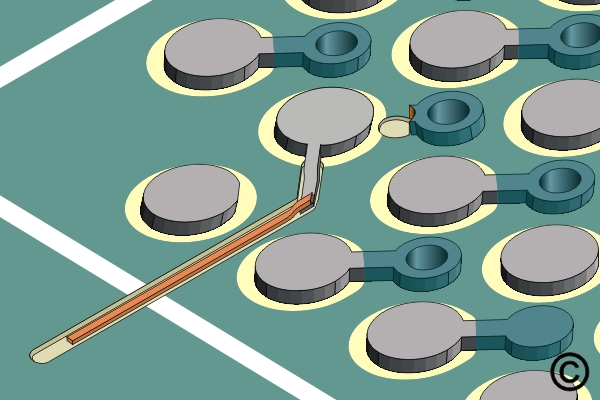

Cut the connection to the via using a Precision Drill System.

Remove the BGA pad and mill a shallow channel into the solder mask surface.

Bond a new BGA pad in place.

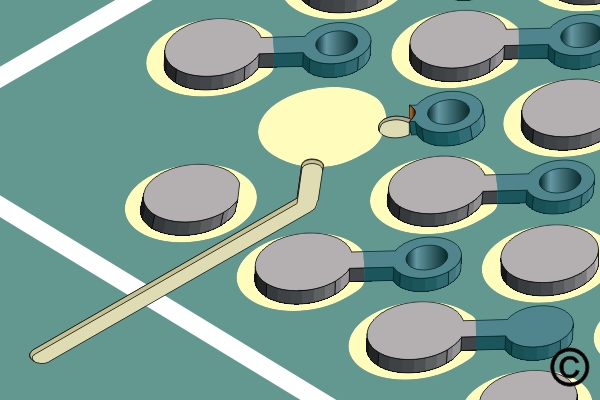

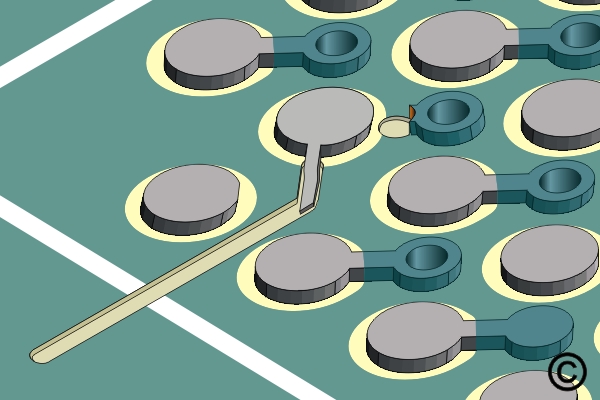

Solder a copper circuit track to the tail extending from the new BGA pad

Solder a wire to the Circuit Track and overcoat with epoxy.

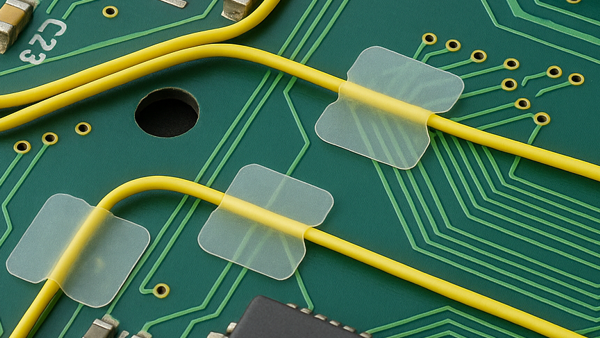

Wire Dots are a thin, flexible polymer film coated on one side with a high-performance, electronics grade permanent pressure-sensitive adhesive.

LEARN MORE

We're here to help with ECO rework, jumper wire adds, circuit cuts, and various complex modifications.

LEARN MORE

SLIDESHOW STARTING

❮

❯