We've all seen and read the news stories in the last several years about how the worldwide pandemic has disrupted supply chains, causing product delays and shortages in many industries. The semiconductor manufacturing and electronic assembly supply chains have not escaped the impact. Procurement and supply chain experts find that specific electronic components are becoming very difficult, if not impossible, to source in some cases.

The salvaging of or harvesting valuable and hard-to-find components from scrap, obsolete, or unneeded printed circuit assemblies is a viable option many companies are seriously contemplating to help bridge the supply gap.

Circuit Technology Center has the experience and expertise to safely and reliably remove and salvage virtually any component type from fully assembly printed circuit boards, including fine pitch QFPs, bottom terminated devices such as BGA's and LGA's, and multi-pin, high-density through-hole connectors.

There are several factors to consider and questions answered before component salvaging, such as:

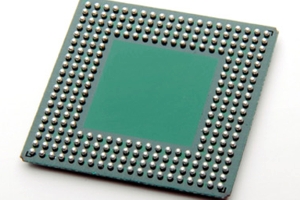

Are the components being salvaged BGA devices? If so, can the parts be re-balled?

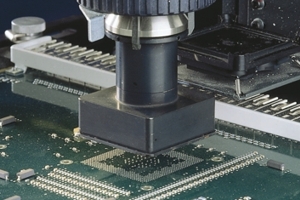

Yes! Circuit Technology Center is the most experienced and trusted source for BGA component re-balling services in the industry. BGA devices, along with other SMT and bottom terminated devices, are carefully and selectively removed from PCBAs using fully programmable, state-of-the-art hot gas rework systems manufactured by Air-Vac Engineering.

BGAs can be re-balled after removal with either tin/lead solder spheres or RoHS-compliant, lead-free solders. We have seven fully staffed Air-Vac rework systems and over 20 years of experience re-balling BGA components for high-rel military/aerospace and commercial applications. High-volume and low-volume requirements are supported, and quick turn delivery is often available.

What is the moisture sensitivity level of the devices being salvaged?

Circuit Technology Center has multiple batch ovens dedicated to MSL (moisture sensitivity level) bake-out. Circuit board assemblies will be pre-baked before device salvage per the device manufacturer's guidelines and per J-STD-020.

Parts are MSL packaged post-processing, including vacuum sealing in an ESD barrier bag with desiccant and a moisture sensitivity card; the sealed package is labeled per J-STD-033 protocols.

Will the components be machine or hand-placed in the upcoming re-assembly process?

It is essential to know the assembly process that will be used with the salvaged components. If the salvaged components are to be hand soldered, as opposed to machine placed, you can loosen the criteria for residual solder left on the leads and lead co-planarity. Less component touch-up time means a less costly salvage process for you.

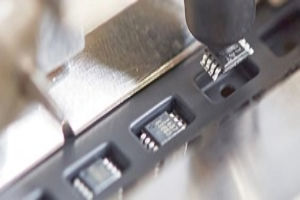

If machine placement is required, component leads can be dipped and re-tinning after salvage by our robotic hot solder dip equipment (RHSD), ensuring excess solder peaks and bridges are removed. All RHSD process parameters, including pre-heat time and temperatures, dwell times, angles, and solder pot temperatures, are fully programmable, ensuring a safe, repeatable, and reliable process.

What is the ESD sensitivity level?

All circuit assemblies and all components should be handled with proper ESD precautions. There are different levels of ESD sensitivity, and understanding the components that you are working with is critical. Circuit Technology Center maintains a stringent ANSI ESD/S20.20 certified ESD program.

What temperature range can the component withstand?

Component salvage can be completed with a variety of processes consisting of localized hot gas, molten solder on a mini-solder wave machine, conduction heat using soldering irons, or de-soldering tools. When performed by one of our certified operators, these are all sound processes and in compliance with IPC-recommended procedures. A review of the component specification by one of our process engineers will provide a safe temperature range to maintain.

Are the circuit boards and components conformally coated, or is there an under-fill applied?

The impact that conformal coating and under-fill have on the component salvage process can certainly be significant. It is important to determine the overall area of the component that the coating must be removed from. In some cases, the critical area is relegated to the solderable surface of the component lead. In other cases, the entire component, including the component body, must be free of coating.

What about packaging, trays, tubes, or tape and reel?

Circuit Technology Center can often source new JEDEC component trays and tubes for safe component storage and transport. We can also use Gel Packs or Waffle Packs. Circuit Technology Center can also support the re-tape and reel of salvaged components in accordance with EIA-481E standards. Quick turn-times are often available.

Contact the experts at Circuit Technology Center if you are considering the salvage and harvest of hard-to-find or valuable components.