|

Outline

This procedure covers the techniques for identifying various coatings so that the appropriate coating removal method can be selected.

Minimum Skill Level - Advanced

Recommended for technicians with soldering and component rework skills and exposure to most repair/rework procedures, but lacking extensive experience.

Conformance Level - High

This procedure most closely duplicates the physical characteristics of the original, and most probably complies with all the functional, environmental and serviceability factors.

| Acceptability References |

| IPC-A-600 2.0 |

Externally Observable Characteristics |

| IPC-A-610 10.0 |

Laminate Conditions |

|

|

|

| Tools, Materials and Supplies |

|

Abrader

Mild abrasive for removing oxides and contaminants.

|

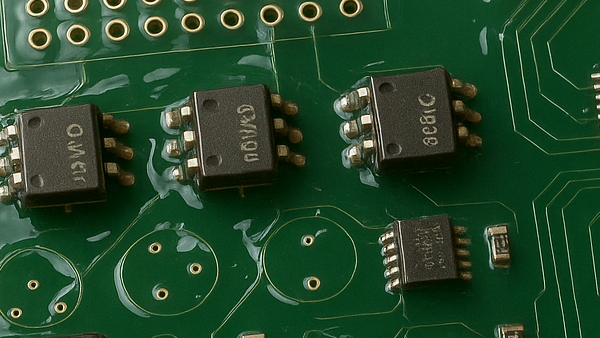

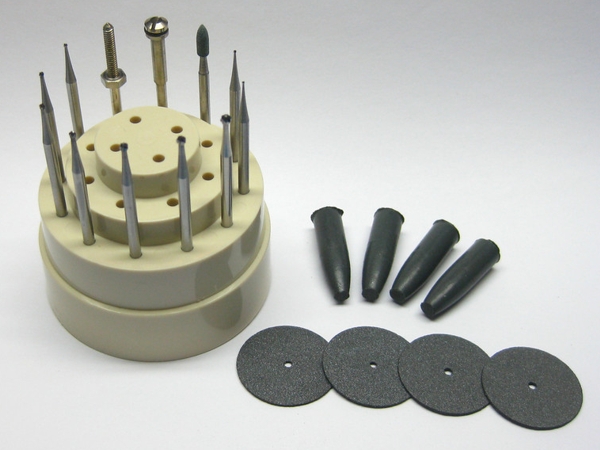

Ball Mills, Abrasives, Cutting Tools

Ball mills, abrasives and cutting tools for working on circuit boards.

|

Cleaning Brushes

Disposable brushes for solvent cleaning and application of coatings.

|

Coating Remover Pen

For precise removal of silicone, acrylic and urethane coatings from circuit boards.

|

Cleaner

General purpose cleaner for removing contamination.

|

Foam Swab, Small

Swabs for use with solvents and application of color agents and epoxies.

|

Knife with #16 Blades

A must-have tool for precise cutting, scraping and trimming.

|

Micro Drill System

Versatile power tool for milling, drilling, grinding, cutting and sanding.

|

Mixing Picks

Disposable mixing sticks for mixing and applying adhesives.

|

Precision Tool Set

Nine precision-crafted tools for detailed circuit board work.

|

Scraper, Curved Tip

Hardened stainless steel tip for scraping solder mask and removing defects.

|

Thermal Parting Tool

Thermal removal tool using controlled heat through specially shaped tips.

|

Wipes

Nonabrasive, low-linting wipes for cleanup.

|

|

|

Procedure

To determine the appropriate coating removal procedure, the coating must first be identified. The specific coating is usually known at the time of its original manufacture. Consequently, the removal methods can generally be specified based on these known coatings. When coating identification is unavailable, simple observation and testing will help identify the coating characteristics to specify the proper removal procedure.

Note: The generic or commercial identification of the coating material is not necessary to accomplish coating removal.

- Hardness

Penetration test in a non-critical area to determine relative hardness. The harder the coating, the more suitable it will be for abrasive techniques. The softer and gummier the coatings, the more suitable they will be for brushing removal procedures.

- Transparency

Transparent coatings are usually more suitable for removal than opaque coatings. Removal methods used with opaque coatings must be far more controllable, less sensitive to damaging the covered components and printed board surfaces, and usually slower.

- Solubility

Test the coating for solubility characteristics in a non-critical area with trichloroethane, xylene, or other solvents with low toxicity and mild activity.

Caution: Printed board assemblies should not be immersed in harsh solvents.

- Thermal Removal

To determine whether the coating can be thermally removed, use a thermal parting device with controlled heating and without a cutting edge. Start with a low temperature, approximately 100 degrees C (210 degrees F), and increase the temperature until the coating is removed. If the coating flows or gums up, you are too hot, or the coating is unsuitable for thermal removal.

Caution: Do not exceed the maximum component storage temperature or other limitations.

- Stripability

Carefully slit the coating with a sharp blade in a non-critical area and try to peel it back from the surface to determine if this method is feasible. Due to the adhesion required of coating materials, strippable techniques without a chemical aid are usually very limited.

- Thickness

Determine if the coating is thick or thin by visual means. Thin coatings show sharp component outlines and no fillets, while thick coatings reduce sharp component outlines and generous fillets at points of a component or lead intersection with the printed board. Thick coatings usually require two-step removal methods to prevent surface damage to the board. First, reduce the thick coating to a thin one and then use pure abrasion methods to reach the board's surface.

The specified coating to be removed may have one or more of these characteristics, and consequently, the removal method selected should consider the composite characteristics.

See Table 1 for Conformal Coating Identification.

See Table 2 for Conformal Coating Removal Methods.

See Table 3 for Conformal Coating Characteristics.

Table 1: Conformal Coating Identification

| Test |

Yes |

No |

| 1. Does the coating feel soft, rubbery, or spongy? |

2 |

3 |

| 2. Does the coating have a noticeable reaction to heat? |

Polyurethane |

4 |

| 3. Is there a reaction to alcohol? |

Acrylic |

5 |

| 4. Is the coating thick, and does it have a dull surface? |

Silicone Thick |

Silicone Thin |

| 5. Does the coating have a noticeable reaction to heat? |

6 |

Paraxylyene |

| 6. Does the reaction form white powder? |

Epoxy |

Polyurethane |

Table 2: Conformal Coating Removal Methods

Conformal

Coating |

Removal Method |

2.3.2

Solvent

Method |

2.3.3

Peeling

Method |

2.3.4

Thermal

Method |

2.3.5

Grinding

Scraping

Method |

2.3.6

Micro

Blasting

Method |

| Paraxylyene |

|

|

1 |

2 |

3 |

| Epoxy |

|

|

1 |

2 |

3 |

| Acrylic |

1 |

|

2 |

3 |

4 |

| Polyurethane |

3 |

|

1 |

2 |

4 |

| Silicone, Thin |

1 |

|

2 |

3 |

4 |

| Silicone, Thick |

|

1 |

|

2 |

|

Note

The preferred order for applying individual removal methods to specific coatings is numerically indicated. These removal methods are listed in ascending order.

Table 3: Conformal Coating Characteristics

| Characteristics |

Conformal Coating Type |

| Epoxy |

Acrylic |

Polyurethane |

Silicone |

Paraxylylene |

| Hard |

X |

|

X |

|

X |

| Medium Hard |

|

X |

X |

|

|

| Soft |

|

|

X |

X |

|

| Heat Reaction |

X |

X |

X |

|

|

| Surface Bond, Very Strong |

X |

|

|

X |

X |

| Surface Bond, Strong |

|

X |

|

X |

|

| Surface Bond, Meduim |

|

|

X |

X |

|

| Surface Bond, Light |

|

|

|

X |

|

| Solvent Reaction |

|

X |

|

|

|

| Smooth Surface |

X |

X |

X |

X |

X |

| Lumpy Surface |

|

|

|

|

|

| Nonporous Surface |

X |

X |

X |

|

X |

| Glossy Surface |

X |

X |

X |

|

|

| Semiglossy Surface |

X |

|

|

X |

|

| Dull Surface |

|

|

|

|

X |

| Rubbery Surface |

|

|

|

X |

|

| Brittle |

X |

X |

|

|

|

| Chips |

X |

X |

|

|

|

| Peels/Flakes |

|

X |

X |

|

X |

| Stretches |

|

|

X |

X |

|

| Scratch, Dent, Bend, Tear |

|

|

X |

X |

X |

|