|

Outline

This procedure outlines the process for reclaiming BGA (Ball Grid Array) and CSP (Chip Scale Package) components for reuse.

|

|||||||||||||||||||||||||||||||||

|

Procedure

Evaluation

|

|||||||||||||||||||||||||||||||||

Images and Figures

Component Reclaim, BGA/CSP Components

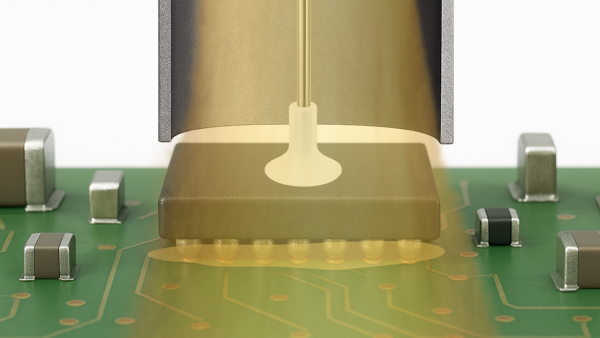

Figure 1. Select the proper nozzle based on the component size.

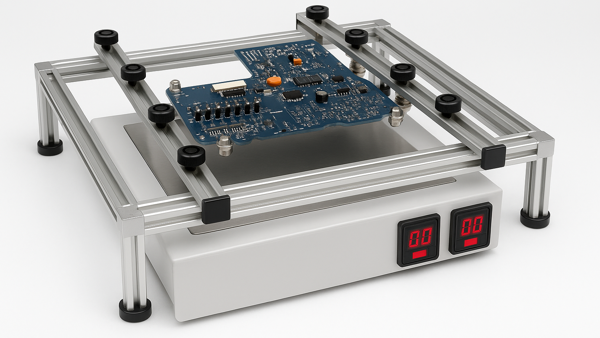

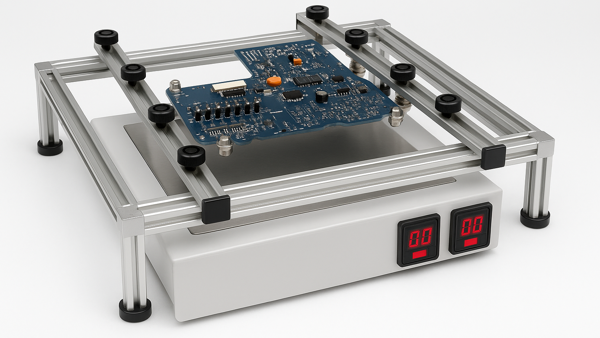

Figure 2. Secure the circuit board in a board holder or on the base of the rework system. A hot plate may be used to provide added bottom-side heating.

Figure 3. Typical hot-air rework tool.

Figure 4. Typical hot-air rework system.

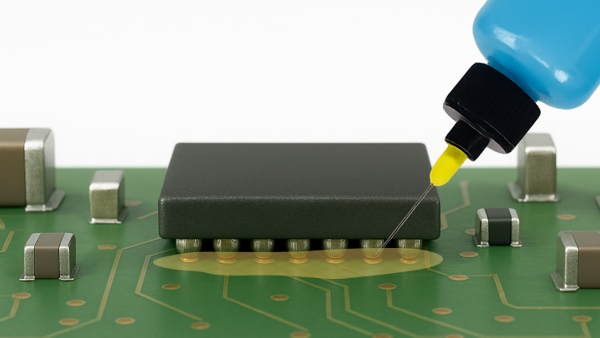

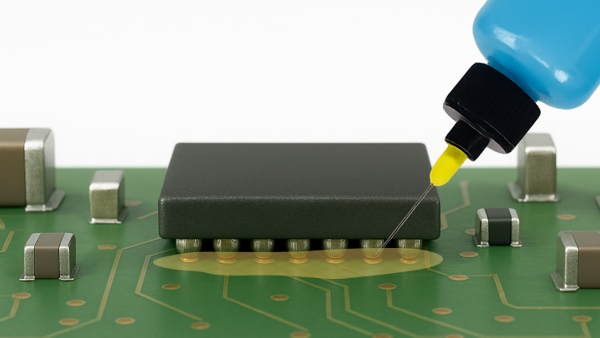

Figure 5. Apply flux to the solder joints.

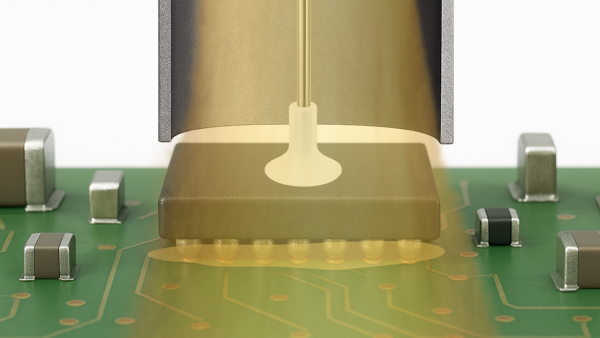

Figure 6. Direct hot air over the component until complete solder melt has been observed. Then lift the component off the board surface.

|

|||||||||||||||||||||||||||||||||

10.9 Component Reclaim, BGA/CSP Components

This procedure outlines the process for reclaiming BGA components for reuse.

Minimum Skill Level: Expert

Conformance Level: High

REQUEST FOR QUOTE GUIDES INDEX

Component Reclaim, BGA/CSP Components

Select the proper nozzle based on the component size.

Secure the circuit board in a board holder or on the base of the rework system. A hot plate may be used to provide added bottom-side heating.

Typical hot-air rework tool.

Typical hot-air rework system.

Apply flux to the solder joints.

Direct hot air over the component until complete solder melt has been observed. Then lift the component off the board surface.

We can relaibly reclaim valuable and hard-to-source components from PCBs using advanced rework systems.

LEARN MORE

SLIDESHOW STARTING

❮

❯