|

Outline

This procedure covers the robotic tinning of axial lead components.

|

|||||||||||||||||||||||||||||||||||||||

|

Procedure

Evaluation

|

|||||||||||||||||||||||||||||||||||||||

Images and Figures

Tinning, Axial Lead Components, Robotic Method

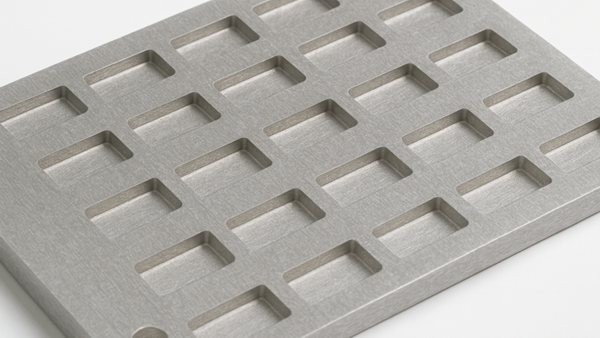

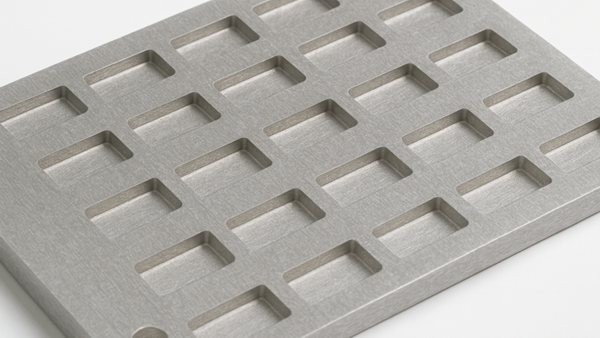

Figure 1. Use a matrix tray or fixture tray to position the components for pickup.

Figure 2. Set up the robotic tinning system with the proper process parameters.

Figure 3. Place the components into the tray and position the tray in the system's staging area.

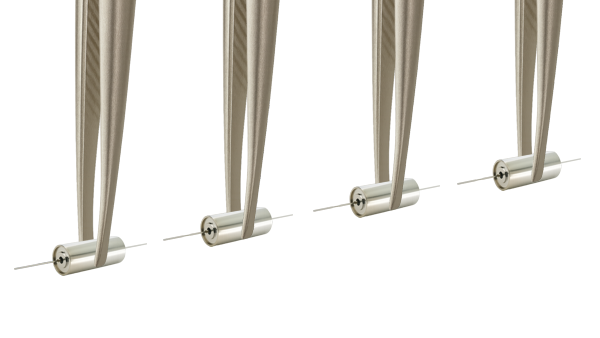

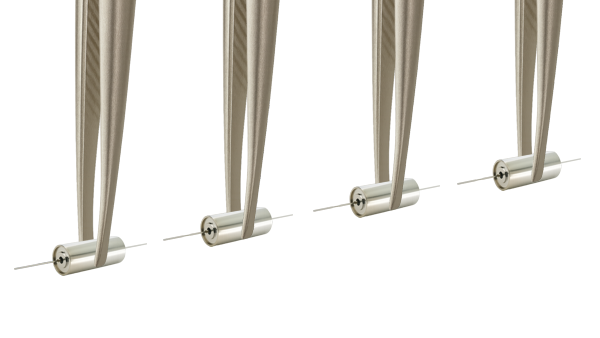

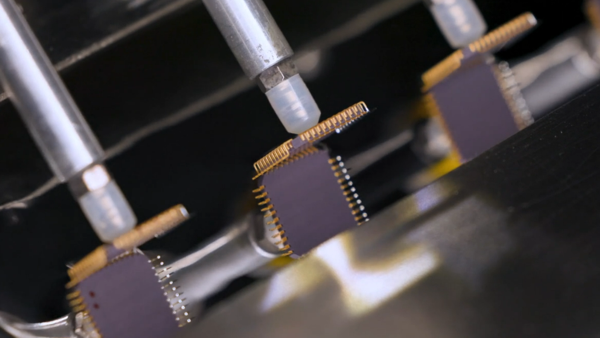

Figure 4. The system will use a multi-head vacuum pickup or mechanical grippers to pick up a row of axial lead components.

|

|||||||||||||||||||||||||||||||||||||||

11.4 Component Lead Conditioning and Tinning, Axial Lead Components

This procedure covers robotic tinning of axial lead components.

Minimum Skill Level: Expert

Conformance Level: High

REQUEST FOR QUOTE GUIDES INDEX

Tinning, Axial Lead Components, Robotic Method

Use a matrix tray or fixture tray to position the components for pickup.

Set up the robotic tinning system with the proper process parameters.

Place the components into the tray and position the tray in the system's staging area.

The system will use a multi-head vacuum pickup or mechanical grippers to pick up a row of axial lead components.

Our robotic component tinning systems modify component leads and terminations with precision and repeatability.

LEARN MORE

SLIDESHOW STARTING

❮

❯