|

Outline

This procedure covers the robotic tinning of chip components.

|

|||||||||||||||||||||||||||||||||||||||

|

Procedure

Evaluation

|

|||||||||||||||||||||||||||||||||||||||

Images and Figures

Tinning, Chip/Discrete Components, Robotic Method

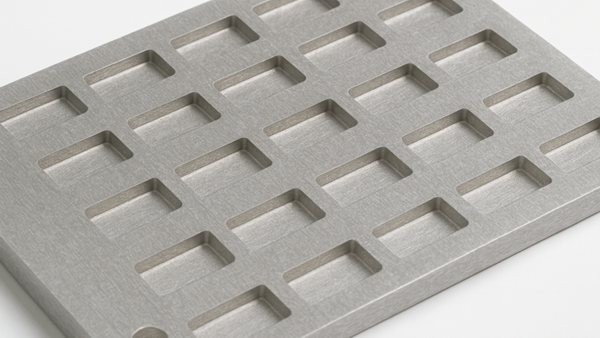

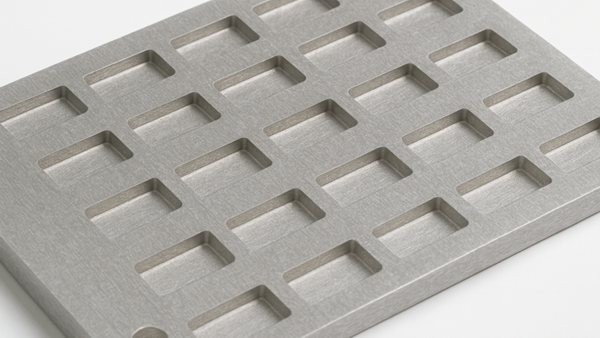

Figure 1. Use a matrix tray or fixture tray to position the components for pickup.

Figure 2. Set up the robotic tinning system with the proper process parameters.

Figure 3. Place the components into the tray and position the tray in the system's staging area.

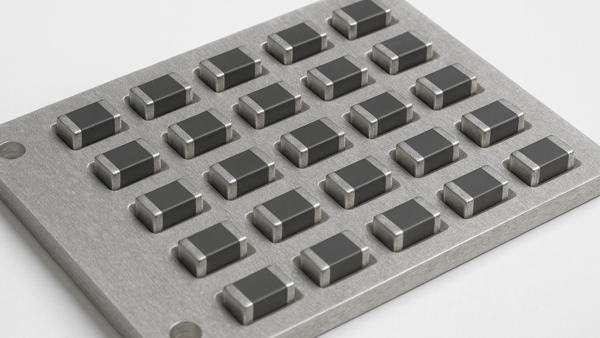

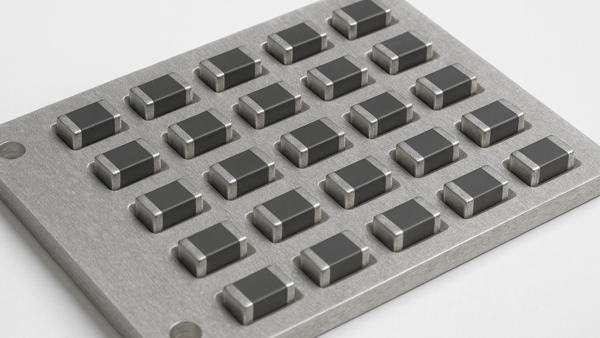

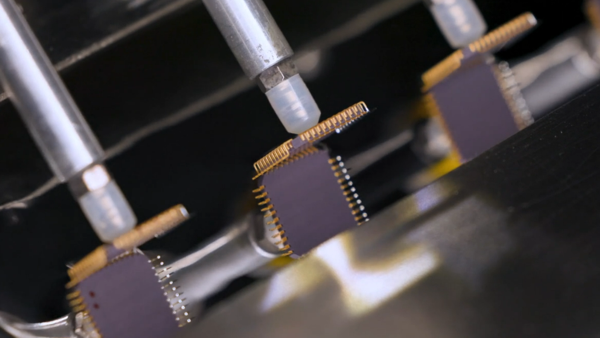

Figure 4. The system will use a vacuum-pickup or mechanical grippers to retrieve one or more components from the tray.

|

|||||||||||||||||||||||||||||||||||||||

11.2 Component Termination Conditioning and Tinning, Chip/Discrete Components

This procedure covers robotic tinning of chip and discrete components.

Minimum Skill Level: Expert

Conformance Level: High

REQUEST FOR QUOTE GUIDES INDEX

Tinning, Chip/Discrete Components, Robotic Method

Use a matrix tray or fixture tray to position the components for pickup.

Set up the robotic tinning system with the proper process parameters.

Place the components into the tray and position the tray in the system's staging area.

The system will use a vacuum-pickup or mechanical grippers to retrieve one or more components from the tray.

Our robotic component tinning systems modify component leads and terminations with precision and repeatability.

LEARN MORE

SLIDESHOW STARTING

❮

❯