Valuable circuit boards are often scrapped due to damage to the base material. However, circuit boards with damage to the base material can be reliably repaired. Knowing how to repair base material damage rather than scrapping the board can indeed make a significant impact on a company's bottom line.

Several well-established procedures exist for reliably repairing base material damage. Damage can include cracks, chipping, burns, delamination, solder mask and legend issues, and more. Damage may occur during rework or result from board design errors, requiring relocation of a tooling hole or an alignment slot.

The following are frequently encountered methods for repairing base material damage.

Base Material Repair, Edge Transplant Method

When damage occurs at the corner or along the edge of a circuit board, new base material is often added to the damaged area. The transplant process is usually completed with a tongue-and-groove joint method.

This method is a bit more complicated if the inner circuitry has been damaged. In those cases, surface wires may be required to restore the electrical connection. The procedure involves preparing a new section of circuit board material of the same thickness and type as the damaged section.

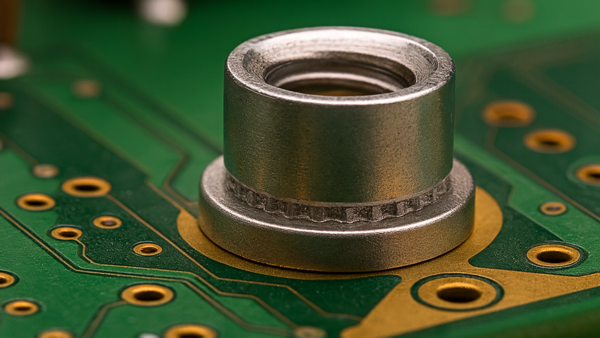

A tongue-and-groove joining method is used for strength. The mating surface of the joining area is coated with a two-part epoxy to secure the new section in place. After the epoxy is fully cured, the area is cleaned of excess epoxy, then milled or cut to meet the original dimensional requirements.

Base Board Repair, Epoxy Method

Often, removing the damaged area and filling it with high-strength epoxy can correct minor base material damage. Coloring agents can be added to the epoxy to blend the repaired location. The repair method is more than cosmetic - repairing the burn or hole prevents moisture and other agents from eventually working their way into the board laminate, causing problems.

This method also restores strength to the area. Burned or frayed material is removed with a ball mill or other appropriate tool to create a clean surface on which the high-strength epoxy can adhere. After the epoxy has cured, the excess is removed to make the new area flush with the surrounding area.