|

Outline

This method is used on circuit boards to replace damaged or missing circuits on the circuit board surface. A length of standard insulated or non-insulated wire is used to repair the damaged circuit.

|

|||||||||||||||||||||||||||||||||||||||

|

Procedure

Procedure

Evaluation

|

|||||||||||||||||||||||||||||||||||||||

Images and Figures

Conductor Repair, Through Board Wire Method

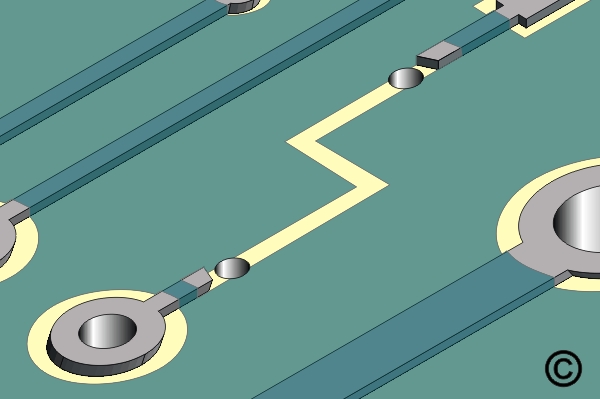

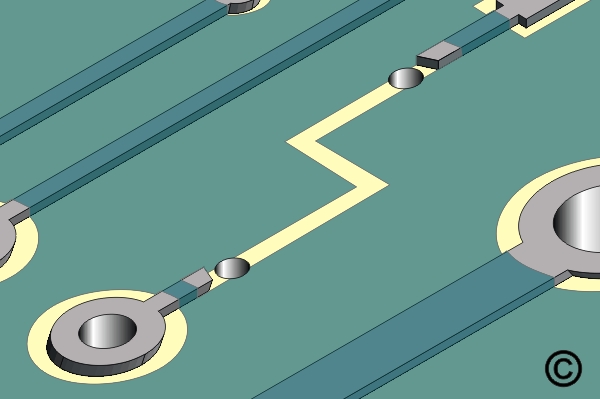

Figure 1. Scrape off any solder mask or coating from the ends of the remaining circuits.

Figure 2. Drill through the board adjacent to both ends of the remaining circuits.

Figure 3. Bend the stripped wire over the prepared circuits in line with the circuits.

Figure 4. Lap solder the wire to the circuits on the circuit board surface.

|

|||||||||||||||||||||||||||||||||||||||

4.2.5 Conductor Repair, Through Board Wire Method

Procedure covers repair of damaged conductors and circuits using a jumper wire feeding through the circuit board assembly.

Minimum Skill Level: Advanced

Conformance Level: Medium

REQUEST FOR QUOTE GUIDES INDEX

Conductor Repair, Through Board Wire Method

Scrape off any solder mask or coating from the ends of the remaining circuits.

Drill through the board adjacent to both ends of the remaining circuits.

Bend the stripped wire over the prepared circuits in line with the circuits.

Lap solder the wire to the circuits on the circuit board surface.

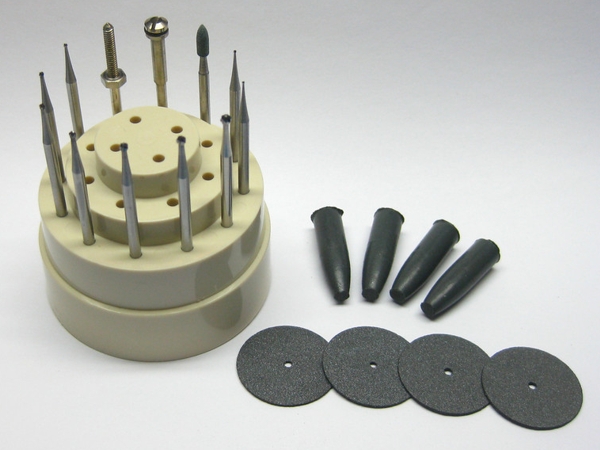

This versatile tool is ideal for milling, drilling, grinding, cutting, and sanding circuit boards.

LEARN MORE

We're here to help with all your challenging circuit board and electronic component rework and repair needs.

LEARN MORE

SLIDESHOW STARTING

❮

❯