|

Outline

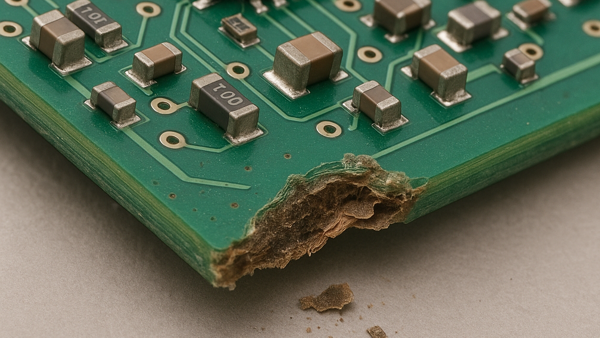

This procedure is used to repair mechanical or thermal damage to the circuit board base material. This method is used when extended areas of base material must be completely replaced. This method may be used on single-sided, double-sided, or multilayer circuit boards or assemblies.

|

||||||||||||||||||||||||||||||||||||||||||

|

Procedure

Evaluation

|

||||||||||||||||||||||||||||||||||||||||||

Images and Figures

Base Material Repair, Area Transplant Method

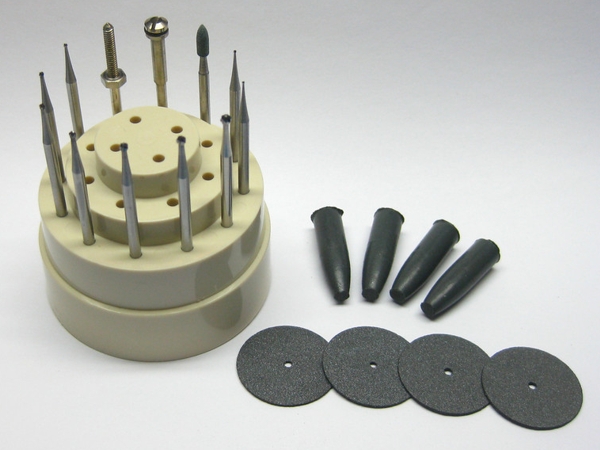

Figure 1. Mill away the damaged base material using the Micro-Drill System and ball mill.

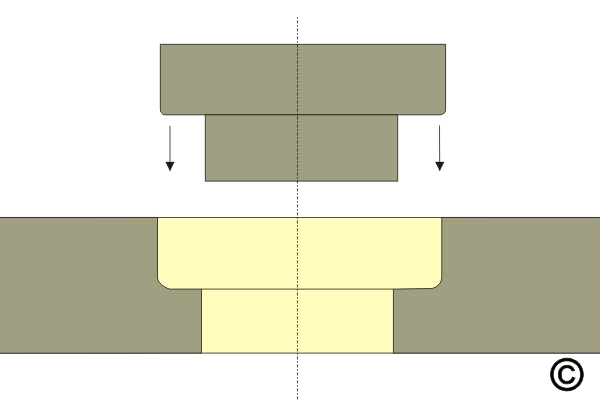

Figure 2. Bevel edge using the Micro-Drill System or file.

Figure 3. Mill a step into the edge of the circuit board.

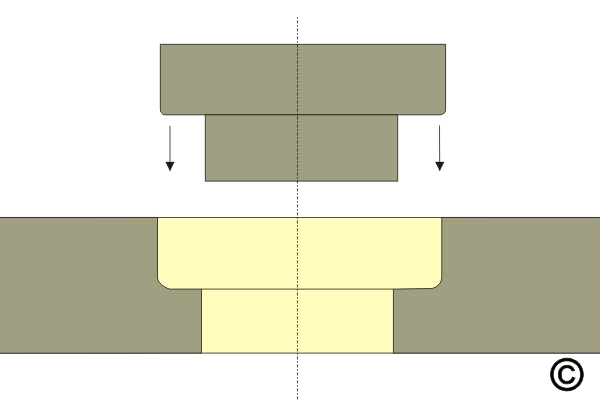

Figure 4. Mill a step onto the edge of the replacement base material.

Figure 5. Bond replacement piece in place.

Figure 6. Completed repair.

|

||||||||||||||||||||||||||||||||||||||||||

3.5.2 Base Material Repair, Area Transplant Method

This procedure covers major repair of damaged base board within the inner area on circuit board assemblies.

Minimum Skill Level: Expert

Conformance Level: High

REQUEST FOR QUOTE GUIDES INDEX

Base Material Repair, Area Transplant Method

Mill away the damaged base material using the Micro-Drill System and ball mill.

Bevel edge using the Micro-Drill System or file.

Mill a step into the edge of the circuit board.

Mill a step onto the edge of the replacement base material.

Bond replacement piece in place.

Completed repair.

This clear, low-viscosity, superior-strength epoxy is ideal for many circuit board repair and rework uses.

LEARN MORE

This versatile tool is ideal for milling, drilling, grinding, cutting, and sanding circuit boards.

LEARN MORE

We're here to help with all your challenging circuit board and electronic component rework and repair needs.

LEARN MORE

SLIDESHOW STARTING

❮

❯