|

Outline

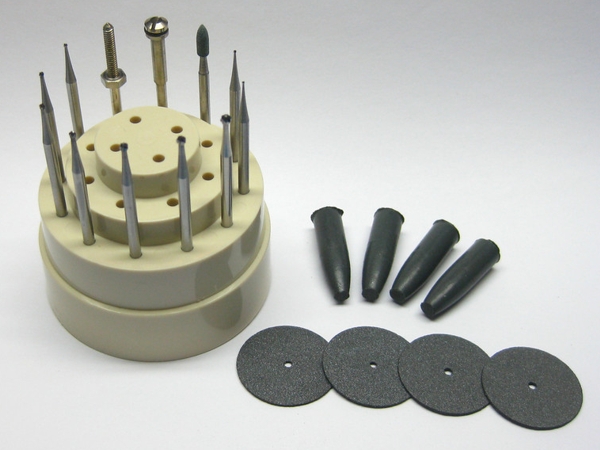

This coating removal method uses various grinding and scraping tools, depending on the composition of the coating material. A knife or dental-style scraper is normally used when a scraping method is desired. A handheld drill is typically used when a grinding technique is preferred. Various rotary abrasive materials, including ball mills, may be required. The coating must first be identified to determine the appropriate coating removal procedure. Refer to procedure number 2.3.1.

|

||||||||||||||||||||||||||||||||||||||||

|

Procedure

Scraping

Grinding

Note: Rubberized abrasives of the proper grade and grit are ideally suited for removing thin hard coatings from flat surfaces, but not for soft coatings, since these would cause the abrasive to "load up" with coating material and become ineffective.

|

||||||||||||||||||||||||||||||||||||||||

Images and Figures

Coating Removal, Grinding/Scraping Method

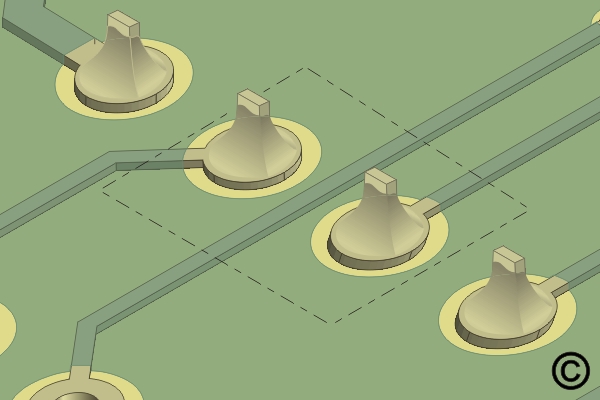

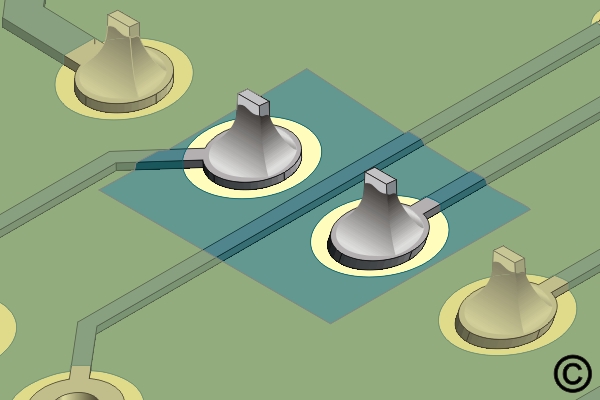

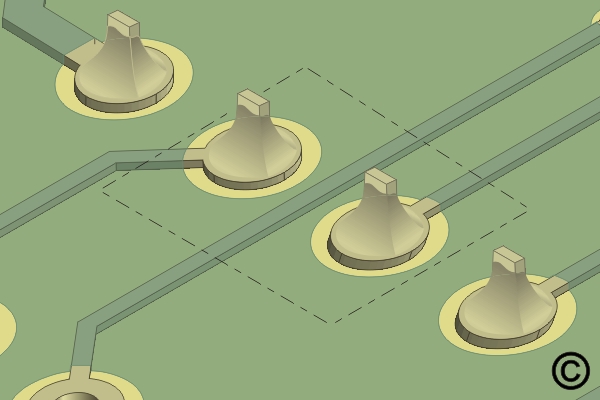

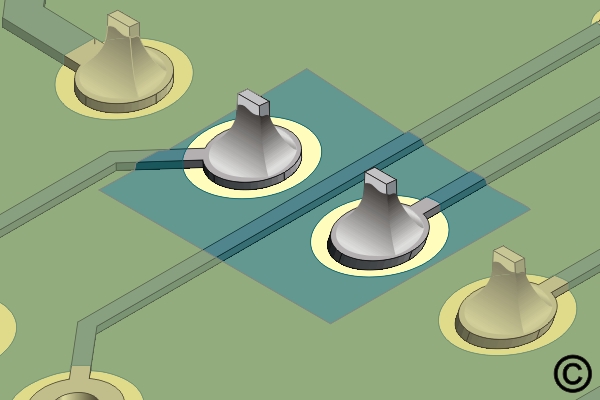

Figure 1. The area requiring coating removal is identified.

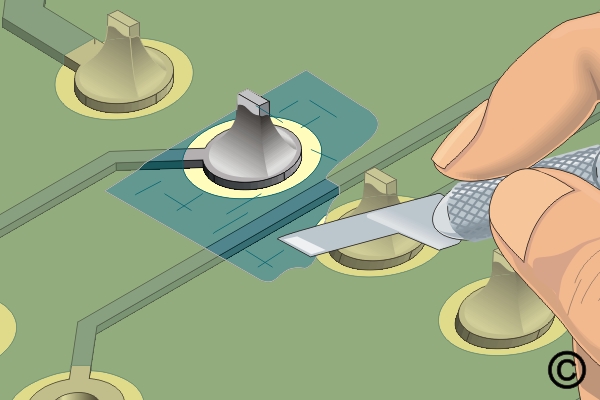

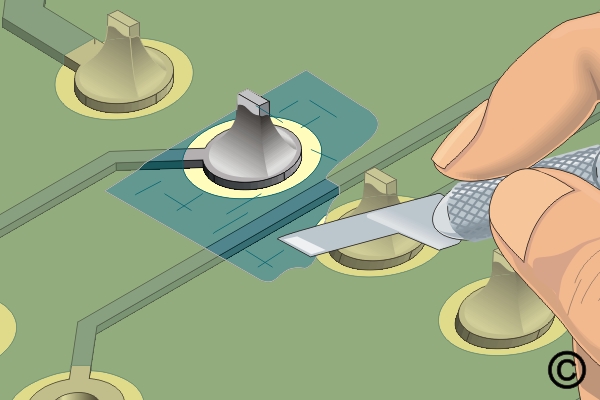

Figure 2. Scrape away damaged or unwanted coating with a knife or scraper.

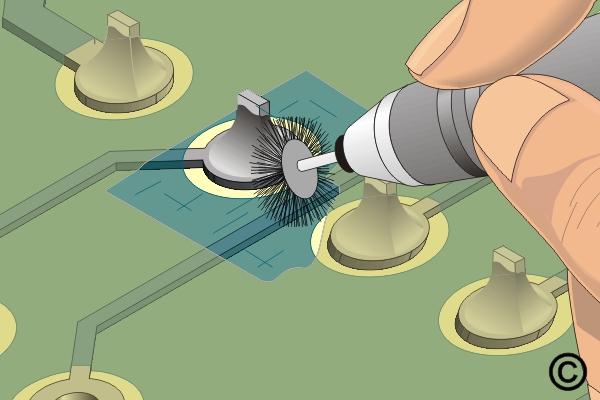

Figure 3. Rubberized abrasives are best used to remove thin, hard coatings.

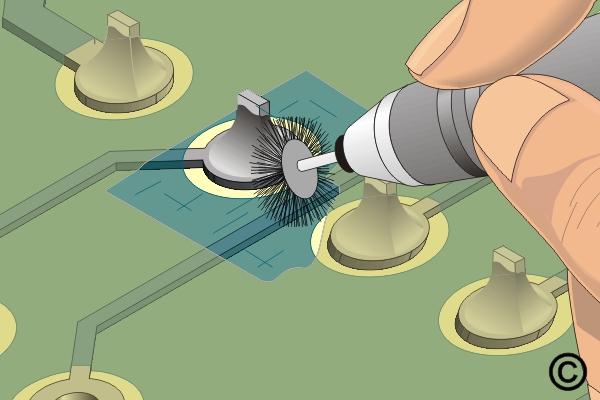

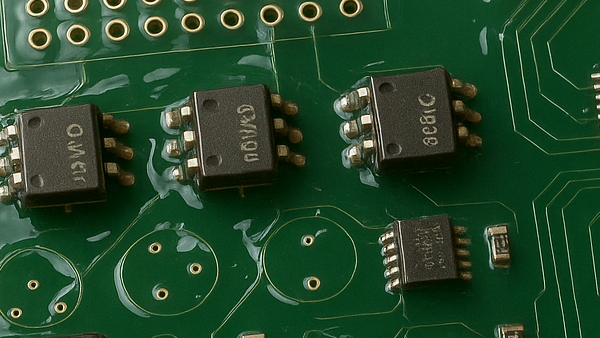

Figure 4. Rotary brushes are best used to remove soft coatings.

Figure 5. Continue as needed until the required coating material is removed,

|

||||||||||||||||||||||||||||||||||||||||

2.3.5 Coating Removal, Grinding/Scraping Method

Procedure covers the methods for removal of coatings on circuit boards assemblies using various grinding and scraping processes.

Minimum Skill Level: Expert

Conformance Level: High

REQUEST FOR QUOTE GUIDES INDEX

Coating Removal, Grinding/Scraping Method

The area requiring coating removal is identified.

Scrape away damaged or unwanted coating with a knife or scraper.

Rubberized abrasives are best used to remove thin, hard coatings.

Rotary brushes are best used to remove soft coatings.

Continue as needed until the required coating material is removed,

This versatile tool is ideal for milling, drilling, grinding, cutting, and sanding circuit boards.

LEARN MORE

We're here to help with coating removal/replacement and other challenging circuit board rework and repair needs.

LEARN MORE

SLIDESHOW STARTING

❮

❯