2.3.3 Coating Removal, Peeling Method

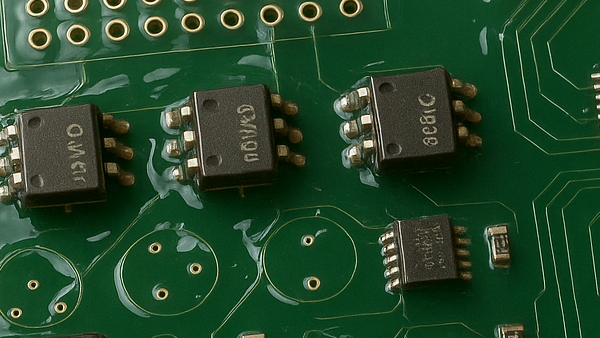

Procedure covers the methods for removal of thick coatings on circuit board assemblies using a peeling method.

Minimum Skill Level: Advanced

Conformance Level: High

REQUEST FOR QUOTE GUIDES INDEX

Coating Removal, Peeling Method

The area requiring coating removal is identified.

Slit and peel off the coating material with a dull knife or heated dull blade.

Repeat as needed until the required material is removed.

This versatile tool is ideal for milling, drilling, grinding, cutting, and sanding circuit boards.

LEARN MORE

This versatile tool is ideal for milling, drilling, grinding, cutting, and sanding circuit boards.

LEARN MORE

We're here to help with coating removal/replacement and other challenging circuit board rework and repair needs.

LEARN MORE

SLIDESHOW STARTING

❮

❯