10.5 Component Reclaim, J-Lead Components

This procedure outlines the process for reclaiming J-Lead components for reuse.

Minimum Skill Level: Expert

Conformance Level: High

REQUEST FOR QUOTE GUIDES INDEX

Component Reclaim, J-Lead Components

Select the proper nozzle based on the component size.

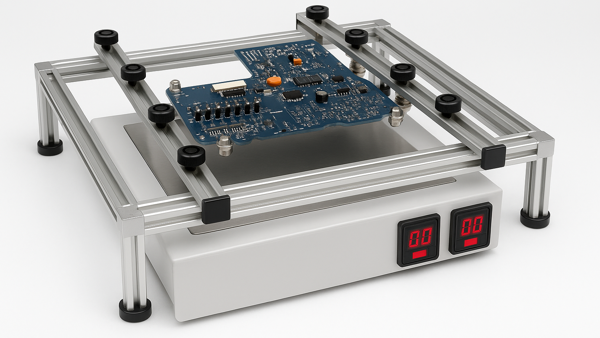

Secure the circuit board in a board holder or on the base of the rework system. A hot plate may be used to provide added bottom-side heating.

Typical hot-air rework tool.

Typical hot-air rework system.

Apply flux to the component terminations.

Initiate the hot gas reflow cycle, observing the solder melt on all leads. Then activate the system vacuum and raise the nozzle and component.

We can relaibly reclaim valuable and hard-to-source components from PCBs using advanced rework systems.

LEARN MORE

SLIDESHOW STARTING

❮

❯