10.3 Component Reclaim, Radial Lead Components Components

The guide covers the basic requirements for reclaiming electronic components for reuse.

Minimum Skill Level: Advanced

Conformance Level: High

REQUEST FOR QUOTE GUIDES INDEX

Component Reclaim, Radial Lead Components Components

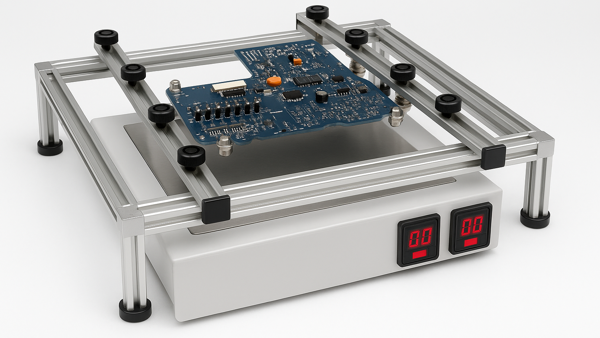

If needed, secure the circuit board in a board holder.

Typical vacuum desolder system.

Apply flux to the solder joints.

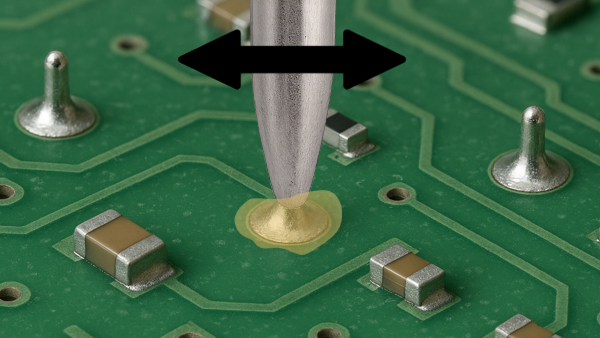

Align the desolder tip with a component lead. Start a rotating or oscillating motion with the desolder tip.

Desoldered joint with the lead detached from the plated hole.

Solder fountain system.

Solder fountain system solder wave.

We can relaibly reclaim valuable and hard-to-source components from PCBs using advanced rework systems.

LEARN MORE

SLIDESHOW STARTING

❮

❯