Once involved in rework and repair, you quickly realize that all the tools you need to get the job done are not always available. It occurs to you that unless you're prepared to make the tool yourself or modify an existing one, you may be stopped in your tracks.

Isolating surface pads from the ground or other connections is a scenario that plays out with remarkable frequency in our facility. Custom tooling is required to make the rework as easy as possible.

You have three options:

- Design and create an entirely new, custom tool.

- Apply an existing tool to a new or unorthodox application.

- Slightly modify an existing tool to address issues of accessibility (fitting between components, under a component, etc.).

The last of the three is the most commonplace in our experience. These modifications — light machining, grinding, and narrowing — are mostly performed on existing tools such as end mills, ball mills, bonding tips, soldering and desoldering tips, and knife blades.

In most cases, the tooling requirements are unique for each job. Therefore, you must modify standard tools to maintain job efficiency. That is why it is crucial to have some level of tool-making and modifying ability in-house.

The nature of rework and repair is such that time is of the essence. In most cases, there is no time to order custom tools. A little creativity, practice, and some essential grinding or cutting tools will generally get the job done.

Here's an interesting example of how an existing tool was modified to create a custom "hole saw" to achieve a specific result. A leading contract manufacturer had received a shipment of assembled circuit boards with a design error. They discovered that the relief for a plated through-hole pad was missing, resulting in the pad being connected entirely to the surface ground plane. (See Figure 2.)

Complicating matters was that approximately 300 of these boards were fully assembled before the error was discovered. Of course, the contract manufacturer was under pressure to deliver working boards to their customer. Who could they turn to in a pinch? They called the experts at Circuit Technology Center to develop a rework solution.

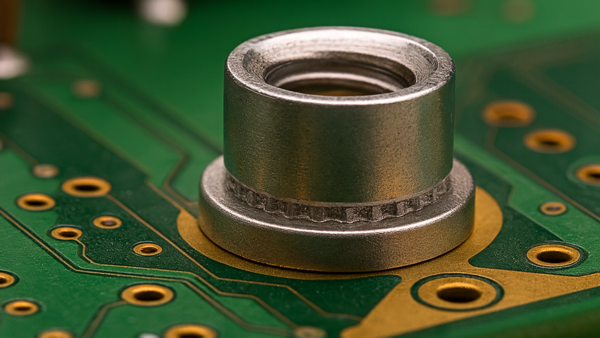

After a thorough examination of tools, options, and existing procedures, one of our engineers proposed using a miniature hole saw to isolate this pad from the ground while leaving enough of the pad intact so that the diode installed at this location could be re-soldered in place. The problem was that no hole saw of this small size existed!

A custom cutter was fabricated by machining away a portion of the cutting end of a carbide end mill, resulting in a tool that would cut a circular pad approximately .020" in diameter. (See Figure 2).

This was another example of how a little imagination and creativity in tool adaptation were used to develop a new, cost-effective rework solution and procedure.