|

Outline

This coating removal procedure uses a controlled, low-temperature, localized heating method to remove thick coatings by overturning or softening them.

|

|||||||||||||||||||||||||||||||||||

|

Procedure

Thermal Parting Method

Hot Air Method

Evaluation

|

|||||||||||||||||||||||||||||||||||

Images and Figures

Coating Removal, Thermal Method

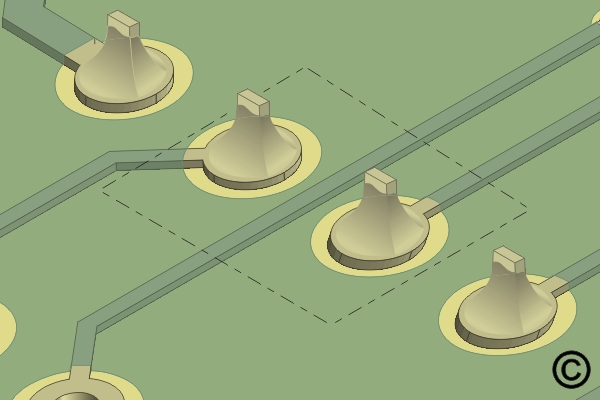

Figure 1. The area requiring coating removal is identified.

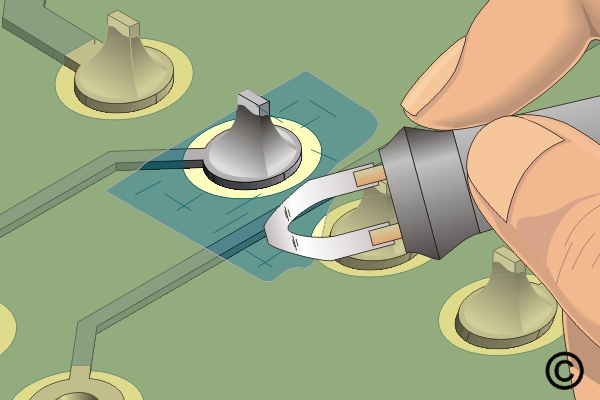

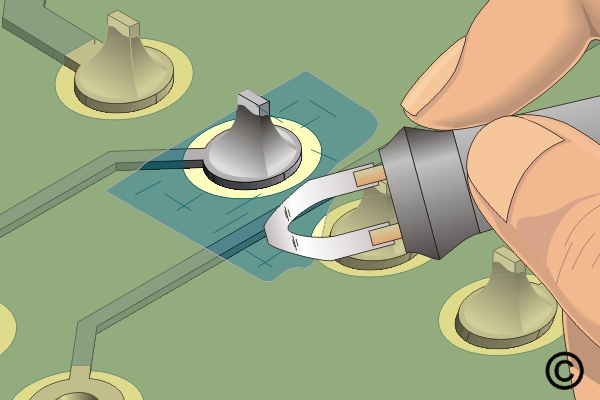

Figure 2. Select an appropriate thermal tip and set the tip temperature. Apply the tip to the coating using light pressure to soften and remove the coating.

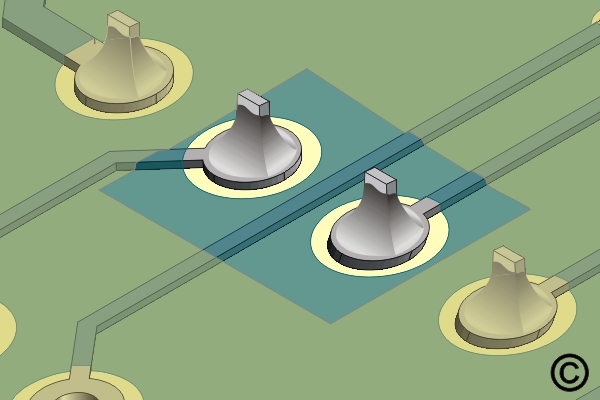

Figure 3. Optionally apply hot air to the work area and use a wood stick to remove the overcured coating.

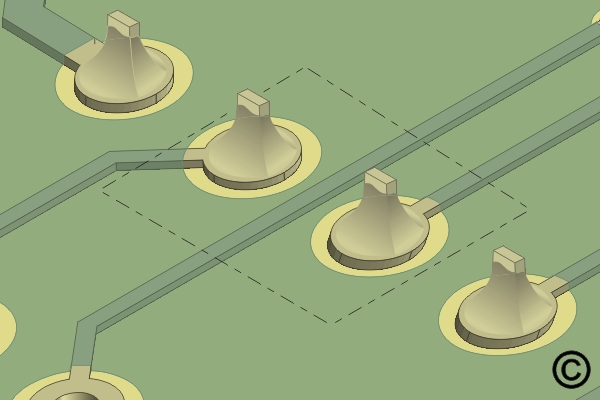

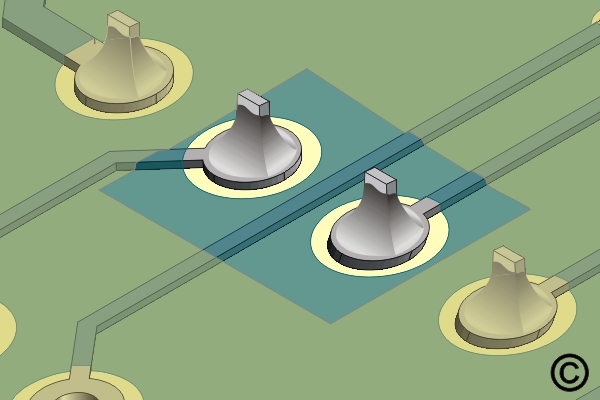

Figure 4. Continue as needed until the required coating material is removed.

|

|||||||||||||||||||||||||||||||||||

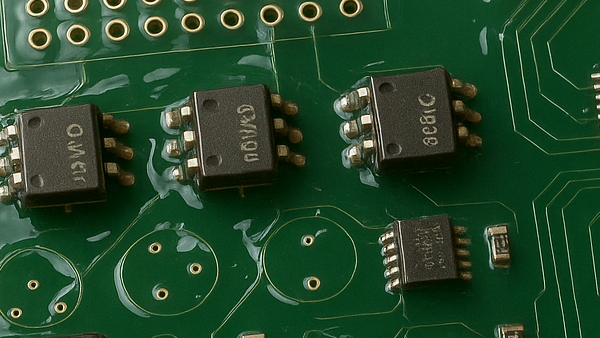

2.3.4 Coating Removal, Thermal Method

Procedure covers the methods for removal of coatings on circuit board assemblies using heat to overcure the coating.

Minimum Skill Level: Advanced

Conformance Level: High

REQUEST FOR QUOTE GUIDES INDEX

Coating Removal, Thermal Method

The area requiring coating removal is identified.

Select an appropriate thermal tip and set the tip temperature. Apply the tip to the coating using light pressure to soften and remove the coating.

Optionally apply hot air to the work area and use a wood stick to remove the overcured coating.

Continue as needed until the required coating material is removed.

This versatile tool is ideal for milling, drilling, grinding, cutting, and sanding circuit boards.

LEARN MORE

We're here to help with coating removal/replacement and other challenging circuit board rework and repair needs.

LEARN MORE

SLIDESHOW STARTING

❮

❯