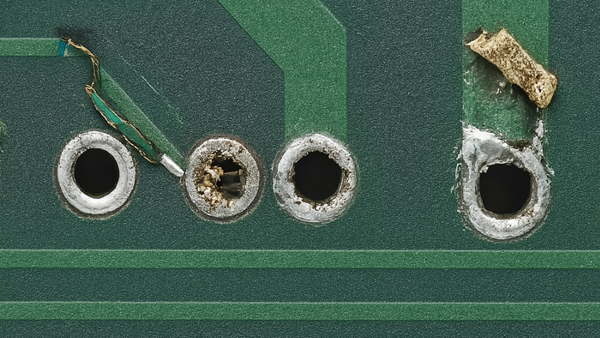

5.1 Plated Hole Repair, No Inner Layer Connection

Procedure to repair damaged plated holes without inner layer connections on circuit board assemblies.

Minimum Skill Level: Intermediate

Conformance Level: High

REQUEST FOR QUOTE GUIDES INDEX

Plated Hole Repair, No Inner Layer Connection

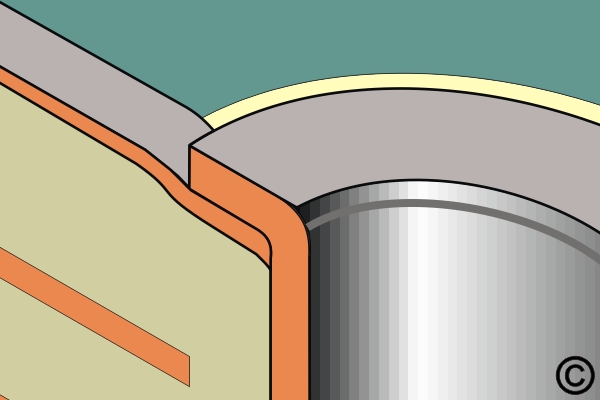

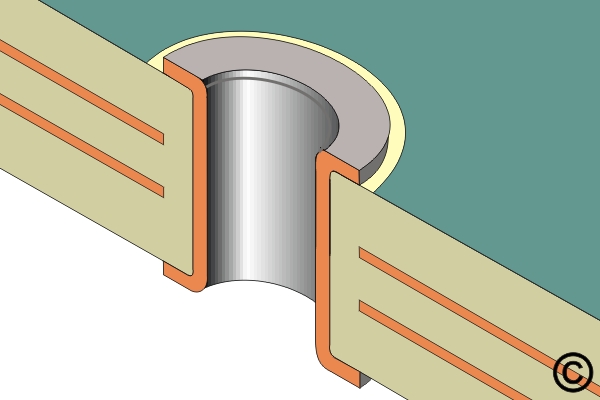

The eyelet flange can be used to secure a new circuit in place.

Completed repair.

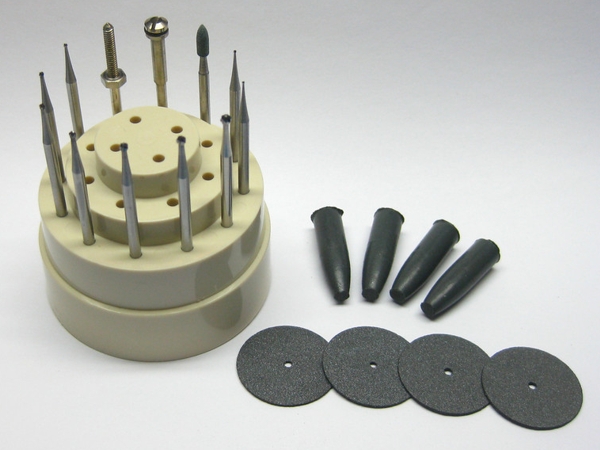

Eyelets are the most common way to repair plated holes conformint to IPC guidelines.

LEARN MORE

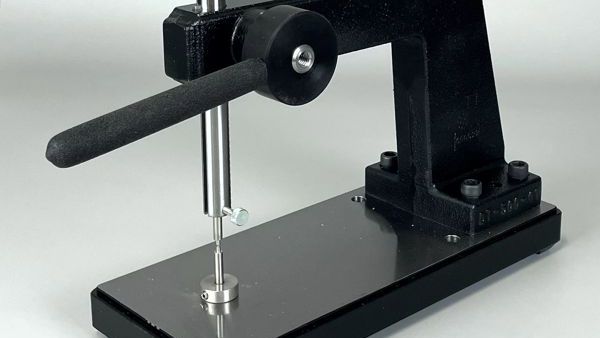

This rugged, heavy-duty press precisely forms eyelets for repair or assembly, ensuring the eyelets meet industry guidelines.

LEARN MORE

We're here to help restore damaged circuitry and plated holes following IPC guidelines.

LEARN MORE

SLIDESHOW STARTING

❮

❯