|

Outline

This coating removal method uses a micro-abrasive blasting system and a very fine, soft abrasive powder. The powder is propelled through a small nozzle toward the area where the coating needs to be removed. The coating must first be identified to determine the appropriate coating removal procedure. Refer to procedure number 2.3.1.

|

||||||||||||||||||||||||||||||||||||

|

Procedure

Evaluation

|

||||||||||||||||||||||||||||||||||||

Images and Figures

Coating Removal, Micro Blasting Method

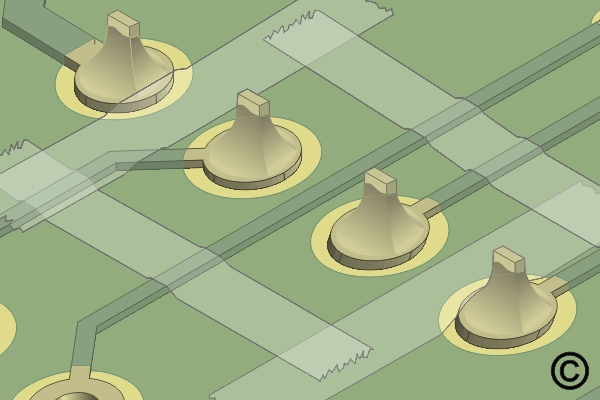

Figure 1. The area requiring coating removal is identified.

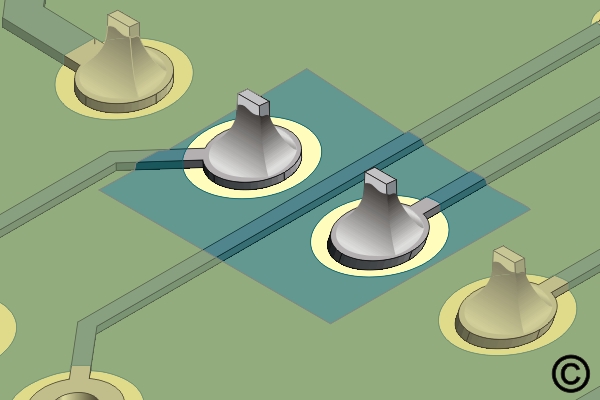

Figure 2. Apply high-temperature tape to outline the area for coating removal.

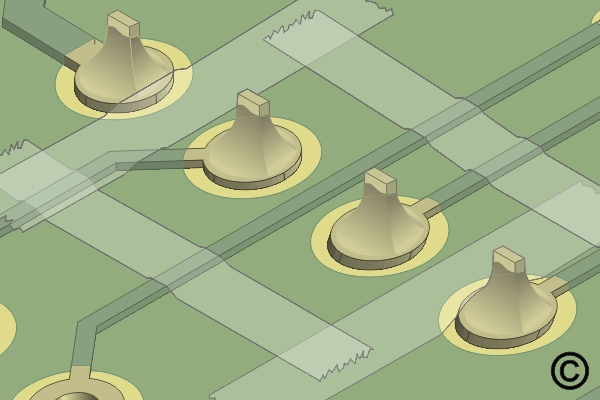

Figure 3. Remove the coating using a micro-blasting system.

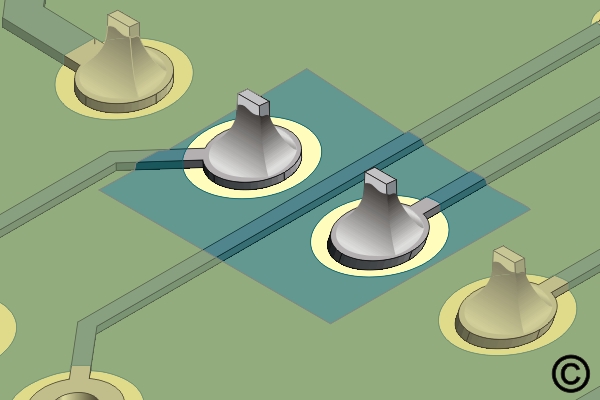

Figure 4. Continue until the required coating material has been removed.

|

||||||||||||||||||||||||||||||||||||

2.3.6 Coating Removal, Micro Blasting Method

Procedure covers the methods for removal of coatings on circuit boards assemblies using a micro abrasive blasting system.

Minimum Skill Level: Expert

Conformance Level: High

REQUEST FOR QUOTE GUIDES INDEX

Coating Removal, Micro Blasting Method

The area requiring coating removal is identified.

Apply high-temperature tape to outline the area for coating removal.

Remove the coating using a micro-blasting system.

Continue until the required coating material has been removed.

This versatile tool is ideal for milling, drilling, grinding, cutting, and sanding circuit boards.

LEARN MORE

We're here to help with all your challenging circuit board and electronic component rework and repair needs.

LEARN MORE

SLIDESHOW STARTING

❮

❯