The 24-Pad Puzzle: Restoring Circuit Boards with USB-C Connector Damage

[unknown placeholder $article.blog_tech_summary$]

REQUEST FOR QUOTE BLOGS INDEX

|

22 Parkridge Road Haverhill, MA 01835 USA www.circuitrework.com |

When a USB-C connector is forcibly removed from a circuit board, the damage often goes beyond a missing part. Given the fine pitch and mechanical stress involved, it's not uncommon for some of the tiny surface-mount pads beneath the connector to lift or tear off completely. That’s exactly what we encountered in a recent repair on a high-density circuit board.

The Challenge: Fine Pitch, Fragile Pads

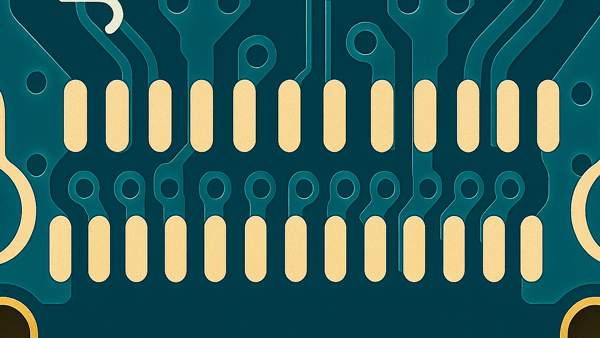

USB-C connectors typically feature up to 24 closely spaced pads. The two rows of 12 pads per row may need to fit into an overall width of 6mm, less than .25". See Figure 1. This compact layout offers functionality but makes the repair process extremely delicate. In this case, when the connector was pulled off, several pads were either lifted or entirely gone—leaving no surface for direct soldering or basic trace repair.

Our Approach: Precision Pad Replacement

To restore full functionality, we used dry-film adhesive-backed replacement pads, carefully selected to match the exact size and shape of the original ones. These pads are designed for both electrical integrity and mechanical strength. Under magnification, each replacement pad was aligned precisely in its original position. We then applied controlled heat and pressure to activate the adhesive, bonding the new pads securely to the circuit board without disturbing adjacent features.

Results: A Reliable, Restored Connection

After replacing and bonding the missing pads, we verified electrical continuity before installing a new USB-C connector. The connector was soldered using precision reflow techniques to ensure clean joints and dependable performance. While this type of repair presents challenges due to the small scale, it’s a potent reminder of what’s possible with the right tools, materials, and expertise. As devices continue to shrink and connector density increases, advanced micro-repair capabilities like this are essential for reliable circuit board restoration.