|

Outline

This process covers the development and criteria for establishing profiles for BGA removal and replacement.

|

|||||||||||||||||||||||||||||||

|

Procedure

Caution - Operator Safety: A thorough review of the equipment manual and comprehensive training is mandatory. Daily maintenance is essential. Consult the equipment manual for more information.

BGA Soldering Profile Instructions

Develop Removal Process

|

|||||||||||||||||||||||||||||||

Images and Figures

BGA Component Rework Profile Development, Standard Method

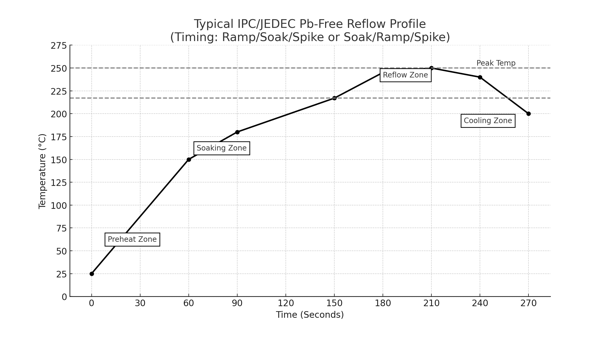

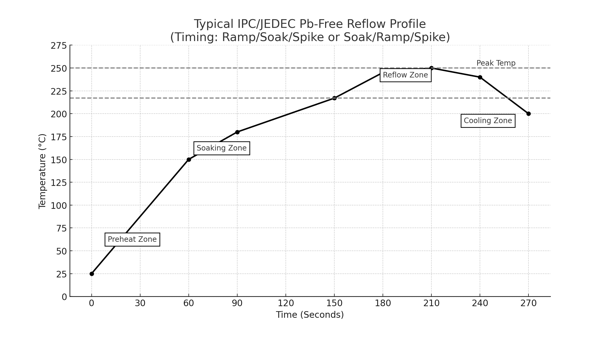

Figure 1. Sample time/temperature profile.

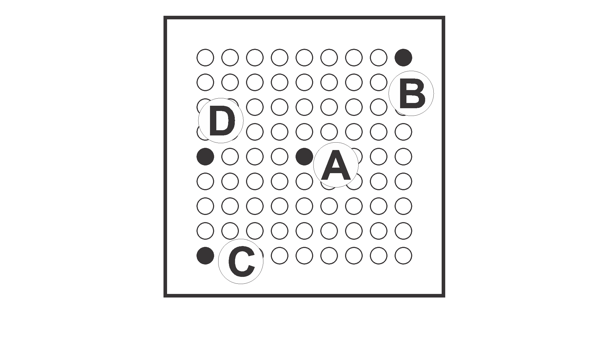

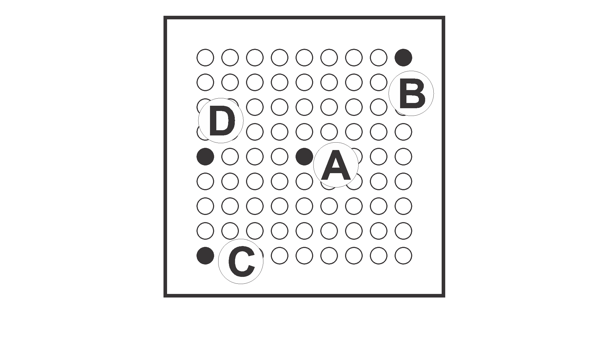

Figure 2. BGA component thermocouple locations

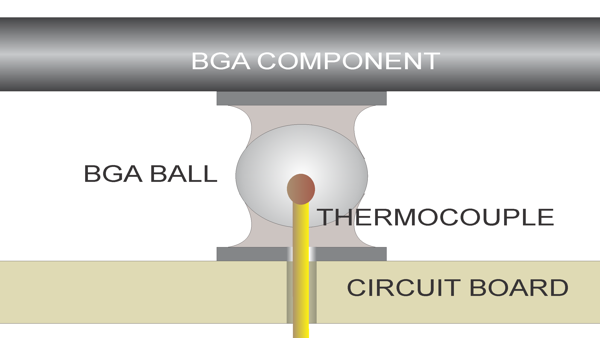

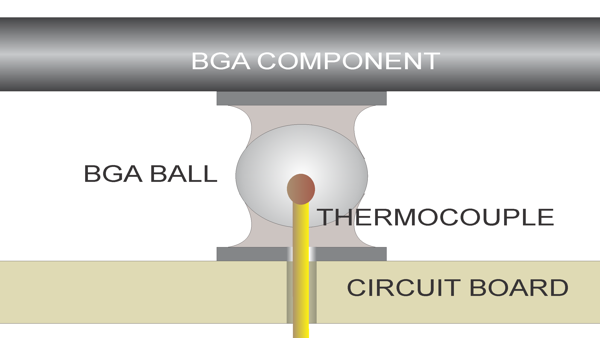

Figure 3. Thermocouple location within the solder ball.

|

|||||||||||||||||||||||||||||||

9.2.1 BGA Component Rework Profile Development, Standard Method

Procedure covers process steps to develop a BGA rework profile on circuit board assemblies.

Minimum Skill Level: Advanced

Conformance Level: High

REQUEST FOR QUOTE GUIDES INDEX

BGA Component Rework Profile Development, Standard Method

Sample time/temperature profile.

BGA component thermocouple locations

Thermocouple location within the solder ball.

For help with BGA rework, contact the globally recognized authority, trusted by aerospace, defense, and electronics manufacturers.

LEARN MORE

SLIDESHOW STARTING

❮

❯