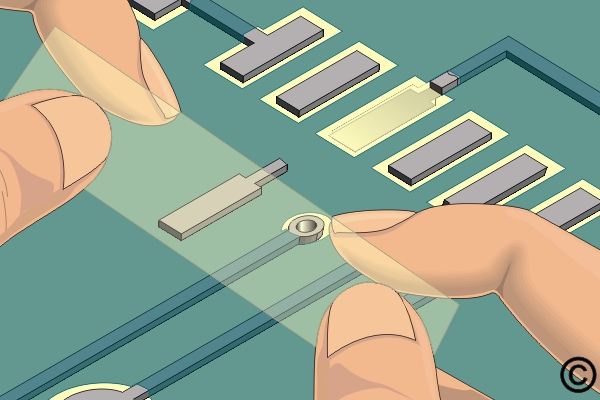

4.7.1 Surface Mount Pad Repair, Epoxy Method

This procedure covers a method to repair damaged surface mount pads on circuit board assemblies using liquid epoxy.

Minimum Skill Level: Advanced

Conformance Level: Medium

REQUEST FOR QUOTE GUIDES INDEX

Surface Mount Pad Repair, Epoxy Method

Remove the defective pad and remove soldermask from the connecting circuit.

Select a replacement pad that matches the missing pad.

Cut out the new surface mount pad.

Place the new surface mount pad in place using high temperature tape.

Completed repair.

Circuit Frames have a dry-film adhesive backing to ensure the delicate repair procedure is easy, fast, and highly reliable

LEARN MORE

You'll appreciate the accuracy of this precision machine when repairing conductors, lands, and surface mount pads.

LEARN MORE

We're here to help with all your challenging circuit board and electronic component rework and repair needs.

LEARN MORE

SLIDESHOW STARTING

❮

❯