Summary

Underfilled BGAs (and other underfilled area-array packages) are increasingly common in high-reliability electronics, especially where vibration, thermal cycling, shock, or warpage control is critical. While underfill improves field robustness, it makes rework dramatically more difficult: traditional thermal removal risks pad cratering, laminate damage, barrel cracking, inner-layer delamination, and collateral damage to adjacent components.

Cold precision milling—a controlled mechanical removal process that uses precision machining to remove the component body and/or underfill while minimizing heat input—provides a compelling alternative for specific use cases:

- Salvaging high-value assemblies when conventional rework risk is unacceptable

- Removing thick/filled underfills that do not respond predictably to thermal softening

- Reducing peak board temperature exposure and cumulative thermal cycles

- Improving control over removal forces and limiting stress transferred into the laminate

This paper explains where cold milling fits in a modern rework toolbox, the process flow, controls, quality validation methods, benefits and limitations, and recommended applications.

The Challenge: Underfill Changes the Failure Modes of Rework

Underfill mechanically couples the BGA body to the PCB, redistributing stress from solder joints into the package and laminate. During rework, this coupling can work against you:

Why thermal removal becomes risky

Thermal BGA removal typically relies on solder reflow and package lift. With underfill present, the package does not "release" cleanly at liquidus. Attempting lift can transfer high peel and shear loads into:

- BGA pads (risk: pad lift, cratering)

- Laminate resin/glass interface (risk: micro-cracking, delamination)

- Plated through vias and barrels (risk: barrel cracking, interconnect fractures)

- Adjacent parts (risk: reflow, tombstoning, latent damage)

Why chemical removal is often impractical

Solvents can be slow, inconsistent across underfill chemistries, hazardous, and difficult to qualify for high-reliability environments. Local containment is challenging, and residues can introduce reliability concerns.

Result: Scrap decisions get made too early

High-value boards, especially those with long-lead components or constrained supply, are often scrapped because the risk of underfill rework exceeds the cost of replacement. A lower-thermal, more controllable option can move that decision point later, preserving value.

What Is Cold Precision Milling?

Cold precision milling is a mechanically controlled removal approach that uses precision tooling and motion control to remove the package body and the bulk of the underfill material.

"Cold" in this context means the process is designed to minimize thermal input (no bulk board heating and limited frictional heating), thereby reducing the risk of thermal damage and preserving board integrity.

Cold milling is not intended to replace all BGA rework. It is best viewed as a specialized, high-control salvage/rework method for difficult underfilled devices.

Where Cold Milling Fits Best

Cold milling is typically considered when one or more of the following are true:

- The assembly is of high value (repair economics justify specialized processing)

- Underfill is thick, highly filled, or high Tg, resisting thermal softening

- The PCB is thin, high-layer count, or HDI, increasing delamination risk

- The BGA is large, high I/O, or close to sensitive neighbors

- Prior thermal attempts have failed or are deemed too risky

- You need to reduce cumulative thermal excursions on mission-critical assemblies

Common application areas

- Defense/aerospace electronics

- Medical devices

- High-end industrial controls

- Advanced compute/AI subsystems where the component value is high

- Legacy assemblies where replacement boards are unavailable

Process Overview

A typical cold precision milling flow follows. Exact steps vary by board design, underfill chemistry, and component geometry.

1. Incoming assessment and risk review:

- Identify package type, pitch, body size, and keep-out constraints

- Confirm underfill presence/type if known (capillary, molded, corner-bond, edgebond)

- Review board construction: thickness, layer count, copper balance, HDI features

- Determine success criteria: salvage vs full rework vs site cleanup only

2. Board stabilization, fixturing, and controls:

- Mechanical removal requires stable constraint and repeatability.

- Rigid, flat support to minimize flex and vibration

- Controlled clamp forces to avoid inducing warpage

- Verified datum strategy for toolpath accuracy

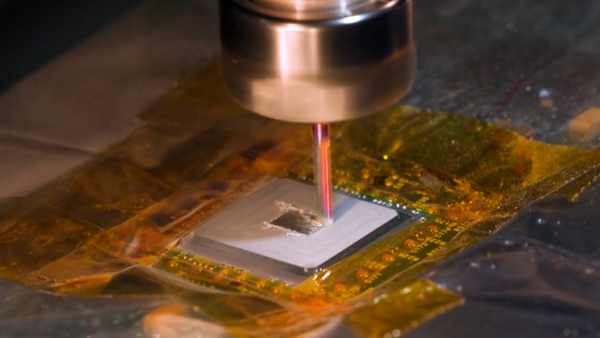

- Fixture Z-axis adjustment to allow for surface flatness irregularities (See Image 1)

- Tool selection (geometry, diameter, coatings)

- Spindle speed and feed rate (reduce chatter and friction heating)

- Depth control and step-down strategy

- Debris extraction and contamination control

- In-process inspection checkpoints

3. Controlled mechanical removal. Depending on the strategy, the process may:

- Remove the package body down to a controlled depth

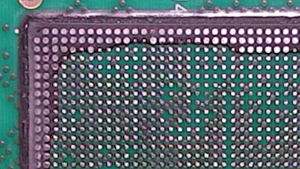

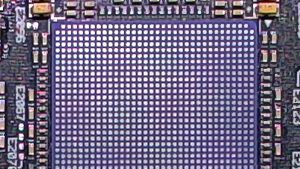

- Selectively remove underfill in the perimeter/interconnect region, often to within .005" of the circuit board pads. (See image 2)

- Separate package remnants while minimizing force into the laminate

4. Residual material removal, site conditioning, and replacement.

- Remaining solder/underfill residues are removed using controlled methods

- Pads are cleaned and conditioned for component replacement

- If required, local mask repair may be completed to prevent solder bridging during replacement

- If the component is replaced, prepare the site

- Place and reflow the replacement device using controlled thermal profiles

- Apply underfill (if required by design) under qualified process controls

Quality and Verification

Cold milling changes the risk profile: it reduces thermal risk but introduces mechanical process controls. A robust verification plan typically includes:

- Site geometry, pad integrity, and solder mask condition

- Verification of keep-out compliance and adjacent part condition

- Confirm no cratering, inner-layer delamination, or barrel cracks

- Validate pad adhesion and laminate integrity

- Continuity and isolation at the site and affected nets

- Functional test when available/required

- Debris and particulate removal verification

- Residue inspection per customer requirements (especially for high-rel)

- No need to heat the entire board to reflow conditions for initial removal

- Lower risk of latent thermal damage and reduced cumulative thermal cycles

- Milling strategy controls how and where loads are applied

- Reduces “lift-force” events that drive pad cratering and delamination

- Works on many high-Tg, filled, or stubborn underfill systems

- More predictable than relying on uncertain softening behavior

- Avoids heating adjacent components into partial reflow states

- Supports selective removal scenarios

Cold milling is powerful, but it is not universal.

- Not always faster than thermal removal for simple cases

- Requires specialized equipment, programming, and operator skill

- If the end goal is "pristine rework-ready pads," results depend on board design, pad construction, and underfill type, original pad adhesion quality, and prior thermal/mechanical history

- Some assemblies may still require a hybrid method using partial thermal assist and mechanical removal

The authors generally recommend cold milling when the cost of failure is high and the assembly warrants a controlled salvage approach.

Typical Use Cases and Decision Guide- High-value board where scrap is unacceptable

- Large underfilled BGA adjacent to heat-sensitive parts

- HDI boards showing known cratering sensitivity

- Prior rework attempts have elevated the risk profile

- Programs requiring tight thermal excursion control

- Underfill is minimal/edge-bond only

- The board is robust, and the replacement cost is low

- The BGA is small, isolated, and known to be reworkable with standard profiles

- Time-to-repair is the overriding constraint, and risk tolerance is higher

Circuit Technology Center approaches cold precision milling as part of a broader advanced rework capability set. Programs are typically executed under a defined process plan that includes:

- Review for rework feasibility

- Controlled fixturing and toolpath planning

- In-process inspection and documented checkpoints

- Optional qualification microsectioning for program confidence

- Documentation packages aligned to customer quality requirements

If your program involves underfilled area-array devices and you are facing high scrap risk, long lead times, or uncertain thermal removal outcomes, CTC can evaluate the assembly and recommend the safest removal pathway.

ConclusionUnderfill is here to stay, and it changes the economics and risk calculus of rework. Cold-precision milling offers a controlled, low-thermal alternative that can increase salvage rates and reduce the risk of latent damage in underfilled BGAs, particularly on high-value, high-reliability assemblies. When deployed with the right controls, inspection, and documentation, it becomes a strategic lever for sustaining programs, mitigating supply constraints, and avoiding unnecessary scrap.