|

Outline

This method repairs mechanical or thermal blisters or delaminations in circuit board laminated base materials. The blister is sealed by injecting a low-viscosity epoxy into the blister/delamination void.

|

|||||||||||||||||||||||||||||||||||

|

Procedure

Evaluation

|

|||||||||||||||||||||||||||||||||||

Images and Figures

Delamination/Blister Repair, Injection Method

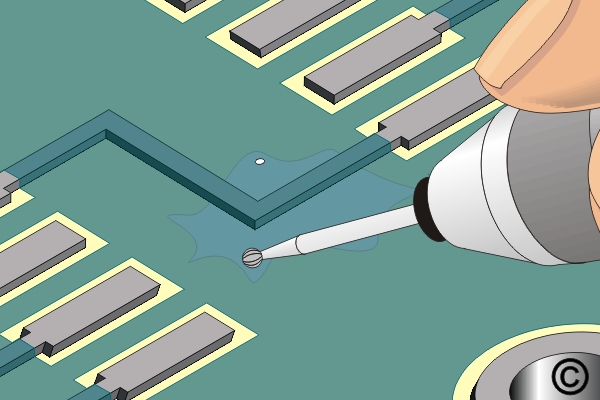

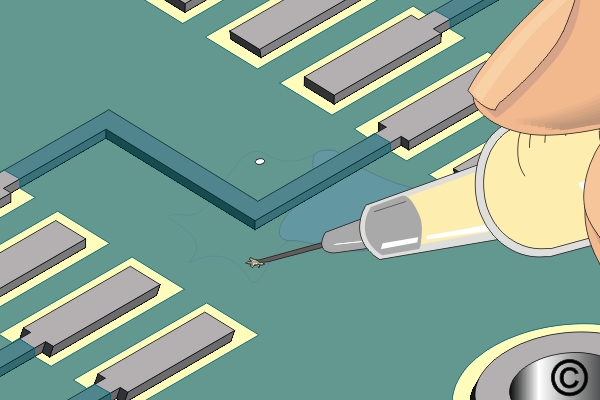

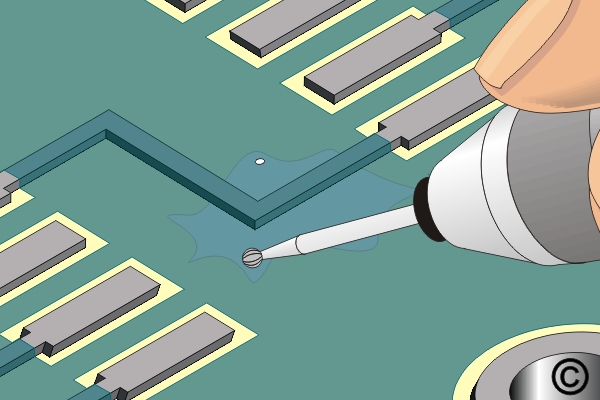

Figure 1. Drill into the delamination blister with the Micro-Drill and ball mill.

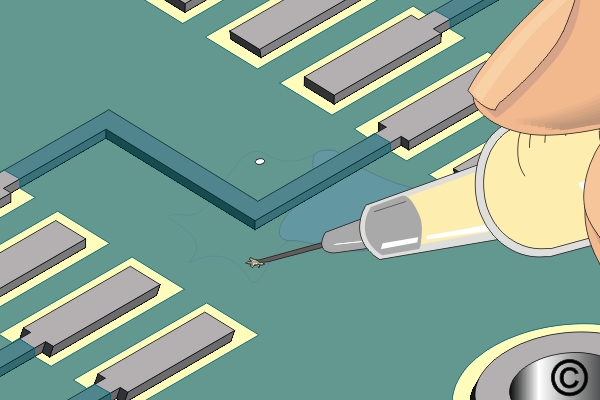

Figure 2. Inject the epoxy into one of the holes in the delamination.

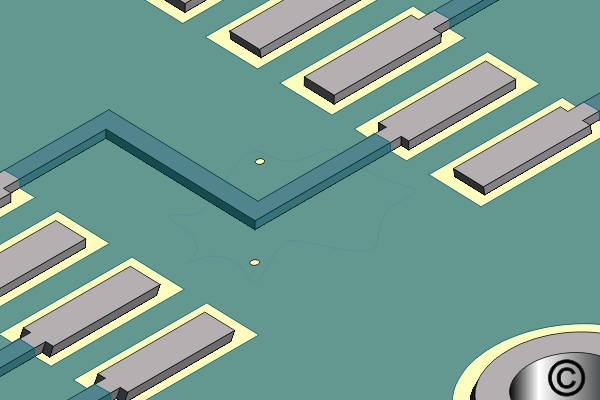

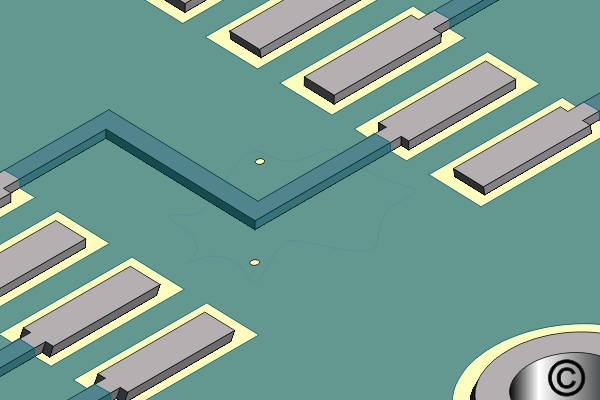

Figure 3. Cure the epoxy per the manufacturer's recommendation.

|

|||||||||||||||||||||||||||||||||||

3.1 Delamination/Blister Repair, Injection Method

Procedure covers delamination and blister repair on circuit board assemblies.

Minimum Skill Level: Advanced

Conformance Level: High

REQUEST FOR QUOTE GUIDES INDEX

Delamination/Blister Repair, Injection Method

Drill into the delamination blister with the Micro-Drill and ball mill.

Inject the epoxy into one of the holes in the delamination.

Cure the epoxy per the manufacturer's recommendation.

This clear, low-viscosity, superior-strength epoxy is ideal for many circuit board repair and rework uses.

LEARN MORE

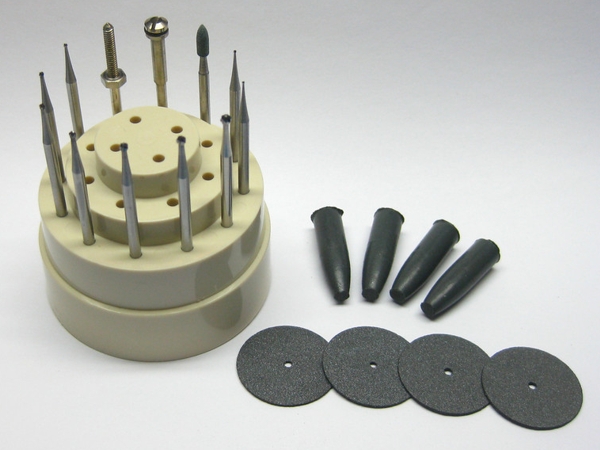

This versatile tool is ideal for milling, drilling, grinding, cutting, and sanding circuit boards.

LEARN MORE

We're here to help with all your challenging circuit board and electronic component rework and repair needs.

LEARN MORE

SLIDESHOW STARTING

❮

❯