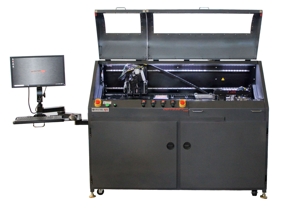

The equipment complies with all applicable GEIA-STD-006, J-STD-001, and IEC TS 62647-4 standards. This state-of-the-art equipment is also used for automated, touch-less BGA component de-balling, required as part of converting BGA’s with lead-free solder to tin-lead solder.

"For nearly 40 years, leading defense and aerospace companies have relied on Circuit Technology Center as the world leader in circuit board level modification and damage repair services," said Andy Price, Sales Manager at Circuit Technology Center. “We are thrilled to announce this capacity expansion, offering our defense and high-reliability customers component level modification and alteration services with the same level of exceptional quality and service that they have come to expect from our company.”