|

Outline

This method modifies or repairs a key slot or other cutout in a printed board or assembly. A replacement piece of matching board material is epoxied into the area needing repair. If needed, a new cut is machined into the repaired area.

|

|||||||||||||||||||||||||||||||||||||||||

|

Procedure

Evaluation

|

|||||||||||||||||||||||||||||||||||||||||

Images and Figures

Key and Slot Repair, Transplant Method

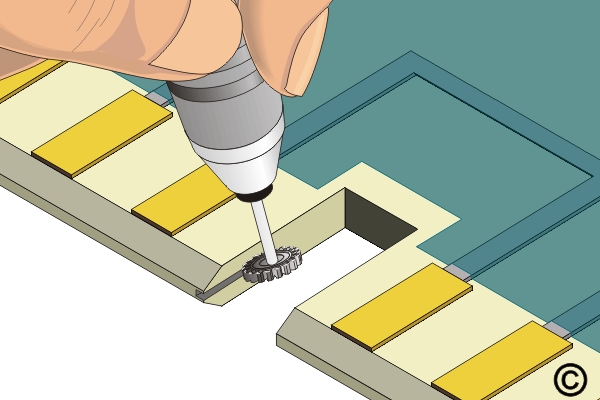

Figure 1. Mill out the damaged area using a milling machine or Precision Drill System.

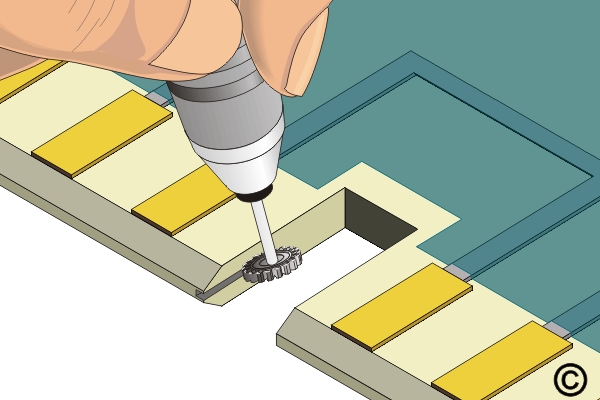

Figure 2. Cut a groove into both sides of the key slot using a Micro-Drill System and carbide saw.

Figure 3. Insert the replacement piece into the slot.

Figure 4. Cut off excess material and file to match edge.

|

|||||||||||||||||||||||||||||||||||||||||

3.4.2 Key and Slot Repair, Transplant Method

This procedure covers major repair of key slots on circuit board assemblies.

Minimum Skill Level: Expert

Conformance Level: High

REQUEST FOR QUOTE GUIDES INDEX

Key and Slot Repair, Transplant Method

Mill out the damaged area using a milling machine or Precision Drill System.

Cut a groove into both sides of the key slot using a Micro-Drill System and carbide saw.

Insert the replacement piece into the slot.

Cut off excess material and file to match edge.

This clear, low-viscosity, superior-strength epoxy is ideal for many circuit board repair and rework uses.

LEARN MORE

This versatile tool is ideal for milling, drilling, grinding, cutting, and sanding circuit boards.

LEARN MORE

We're here to help with all your challenging circuit board and electronic component rework and repair needs.

LEARN MORE

SLIDESHOW STARTING

❮

❯