X-Ray System Eye Opener

|

|

|

|

Figure 1: Old machine void view.

|

Some time ago, we had the good fortune to obtain a Dage X-Ray machine. For years, we used an older machine that had been a reliable workhorse.

Since we loved our old machine, we didn't immediately recognize what the Dage machine could do for us, but when we saw how it performed, well, all we can say is, "What an eye-opener!"

The Dage x-ray systems are a new breed of 2D machines that can rotate the beam receiving head, making the Dage more like a two and a half D machine. Take a look at the following images.

|

|

|

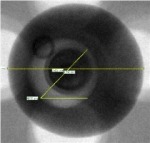

Figure 2: New machine void view.

|

Figure 1 is from the old x-ray machine, and Figure 2 is from the Dage machine. In both images, you can see a sizable void in the ball, but with the new machine, we can get a better view of the characteristics of the void; its size, location, and scope.

In Figure 3, we tilted the board in the older machine to see if we could duplicate the view of the Dage and as you can see, it doesn't come close.

The angling of the head in the Dage provides perspective on the ball and void that is just not available in the older machine.

|

|

|

Figure 3: Old machine angled view of void.

|

Additionally it is hard not to notice the clarity of the image, which is part of the reason we can magnify the image without distortion

Frequently, customers ask us to take a backed off x-ray shot of a BGA component to record the component appearance post-assembly.

In Figure 4, you can see the distortion at the edges of a 42.5 MM component in the picture taken with the old machine.

|

|

|

Figure 4: Backed off image on old machine.

|

On the other hand, as you can see in Figure 5, the component maintains its form in the photo. Further, the Dage pictures maintain their clarity when the customer zooms in to examine specific features in practice.

Another nice feature of the new machine is the ease of measurement. A somewhat laborious calibration was required on the old machine prior to accurate measurement. On the Dage, it's measure at will.

In the case of the void we focused on earlier; you can get a quick view of the size of this void relative to the size of the overall ball in a heartbeat. See Figure 6.

|

|

|

Figure 5: New machine backed off image of same component.

|

We still haven't explored the expansive capabilities of this new machine. There are measurement and comparison routines for the ball, through-hole and void measurement, and other automatic features we don't completely appreciate yet.

But as you can see from the images above, we are already reaping the benefits of the upgraded technology.

There are several machines (if you search the internet, you will come up with a wide variety of reputable companies.

We happen to have the Dage that provides this angled type viewing, and we are quite enthusiastic about the advantages these new machines provide.

|

|

|

Figure 6: Void and ball measurement on the new machine. The void diameter is about .40 MM and the ball itself is .86 MM.

|

If you want to improve your view of x-ray images from the old straight shot 2D imager, we highly recommend you give this type of machine serious consideration.

Several members of the Circuit Technology Center team contributed to this feature story.

|

|

|

|

|