6.5 Component Trim and Form

Procedure covers methods for triming and forming leads on electronic components.

Minimum Skill Level: Expert

Conformance Level: High

REQUEST FOR QUOTE GUIDES INDEX

Component Trim and Form

Determine the finished component lead formed dimensions.

If the component being processed has a plastic tie bar or frame, it may be necessary to trim this tie bar before processing.

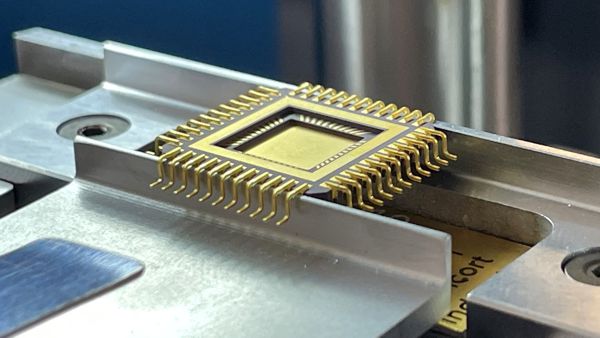

Trim and form machine performing the cutting and forming operations.

See the procedure for detailed instructions.

Get precision component trimming and lead forming to your exact specs at Circuit Technology Center.

LEARN MORE

SLIDESHOW STARTING

❮

❯