2.2.1 Cleaning, Local

Procedure covers localized cleaning of circuit board assemblies.

Minimum Skill Level: Intermediate

Conformance Level: High

REQUEST FOR QUOTE GUIDES INDEX

Cleaning, Local

Cleaning a circuit board with an aerosol spray.

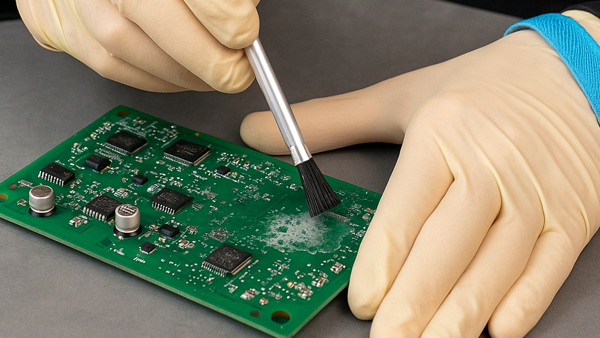

Using an acid brush to remove heavy contaminants.

We're here to help with all your challenging circuit board and electronic component rework and repair needs.

LEARN MORE

SLIDESHOW STARTING

❮

❯