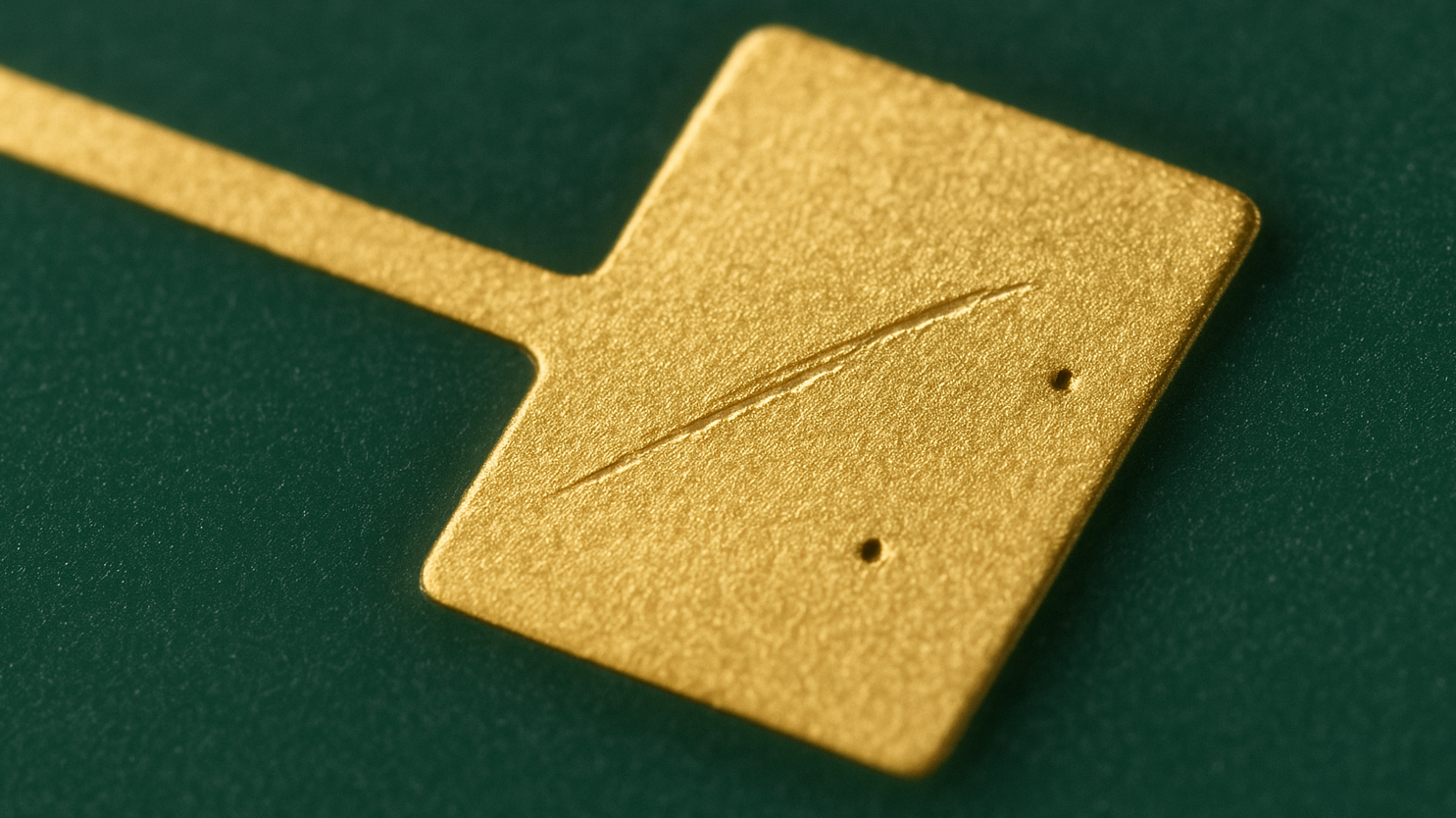

Gold edge contacts are essential for reliable connections in high-performance electronics but are prone to damage from solder contamination, plating wear, and dimensional issues. Circuit Technology Center specializes in restoring these contacts using IPC-recommended processes that ensure conductivity, durability, and mechanical integrity. Our technicians employ a proven brush plating method, utilizing meticulous surface preparation, selective masking, and controlled electroplating with high-purity gold. The result is a uniform finish meeting stringent thickness, hardness, and adhesion standards. We return contacts to like-new condition, ensuring reliable mating, optimal signal integrity, and long-term performance.

Key Highlights

- Specialists in restoring damaged gold edge contacts

- IPC-recommended brush plating process for reliable results

- Skilled technicians with decades of precision experience

- Proven surface preparation and selective masking methods

- Durable, uniform gold finish for extended lifecycle

- Trusted partner for aerospace, defense, and high-performance electronics

- Fully compliant with IPC 7711/7721 repair standards

Technical Specifications

- Restoration of gold edge contacts affected by solder, wear, or damage

- Brush plating process using high-purity gold

- Careful surface preparation and selective masking

- Controlled electroplating for precise finish application

- Meets stringent standards for thickness, hardness, and adhesion

- Restores conductivity, mechanical integrity, and signal performance

- IPC 7711/7721-compliant process for rework and repair

Compliance / References

- 4.6.3 Edge Contact Repair/Rework, Plating Method

- IPC-7711/7721 Rework, Modification, and Repair of Electronic Assemblies

- IPC-A-600 Acceptability of printed boards

- IPC-A-610 Acceptability of Electronic Assemblies

- IPC-J-STD-001 – Requirements for Soldered Electrical and Electronic Assemblies

- IPC-TM-650 TEST METHODS MANUAL (XRF)

- IPC-JEDEC-J-STD-020 Moisture/Reflow Sensitivity Classification for Nonhermetic Surface Mount Devices

- IPC-JEDEC-J-STD-033 Handling, Packing, Shipping, and Use of Moisture, Reflow, and Process Sensitive Devices

- ASTM B488 (International standard) Gold plating

- JESD625C.01 Requirements for Handling Electrostatic-Discharge-Sensitive (ESDS) Devices

- MIL-DTL-45204 (Department of Defense) Gold plating