Solder Joint Opens - What To Do?

|

|

|

|

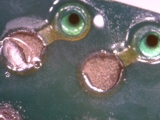

Non wetted pads due to heavy oxidation.

|

Electronic components are soldered to circuit boards every day, and in some cases, opens are found during x-ray inspection or test. You may be inclined to re-heat and reflow the solder using a little extra flux. It's reasonable to think this will work, but it can be deflating when ineffective.

The process may be repeated at higher temperatures or for a longer cycle in a desperate attempt to correct the defect. Yet again, the opens may remain.

While attempts at secondary reflow may often work successfully, it will not work when there are pads with high oxidation levels. The only way to reliably rework this defective solder joint is to remove the component, condition the pads by removing the oxidation followed by tinning, and finally reinstalling the component.

|

|

|

Partially wetted pads.

|

Multiple heat cycles not only overheat the components but also overheat the pads and solder mask, especially when higher lead-free solder temperatures are required. Multiple heat cycles can also negatively impact adjacent components and solder joints.

Some common side effects are damage to component packaging, fractured solder joints, and baseboard discoloration. Ask anyone who has pressed down on a component with an open to see it function properly but then when the pressure is removed, the open returns. It is a perplexing situation.

After the first attempt at secondary reflow, the best practice is to either remove the component and investigate the situation or send the circuit board to a specialist for rework.

Several members of the Circuit Technology Center team contributed to this feature story.

|

|

|

|

|