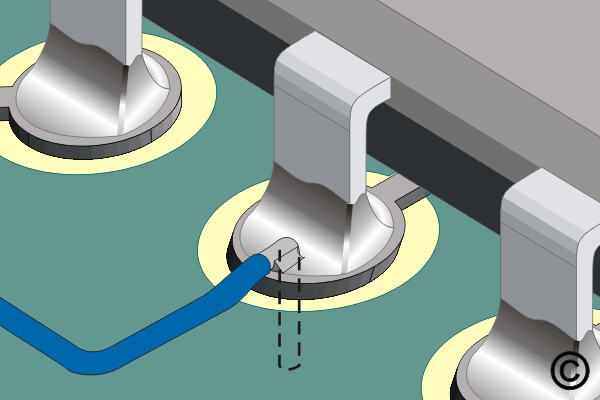

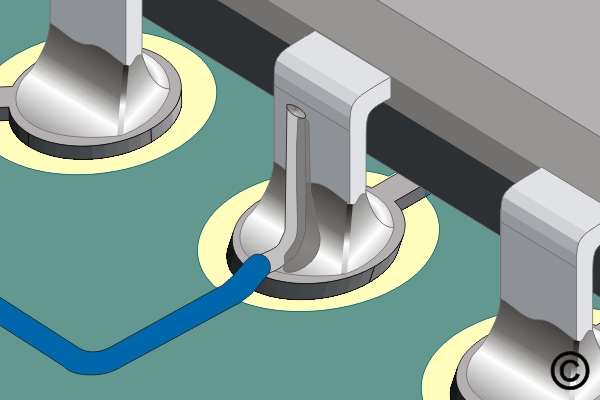

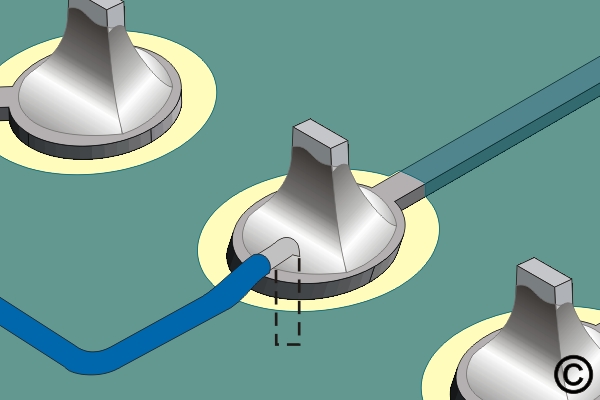

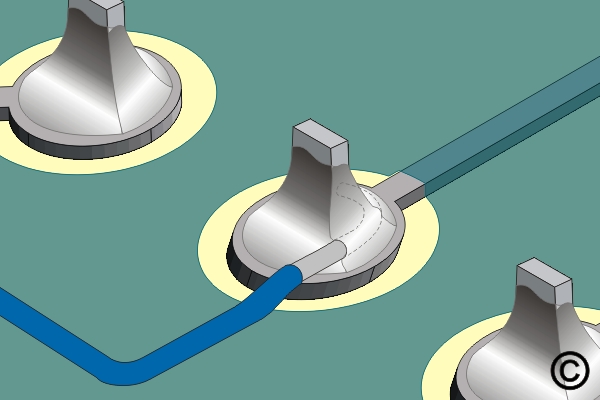

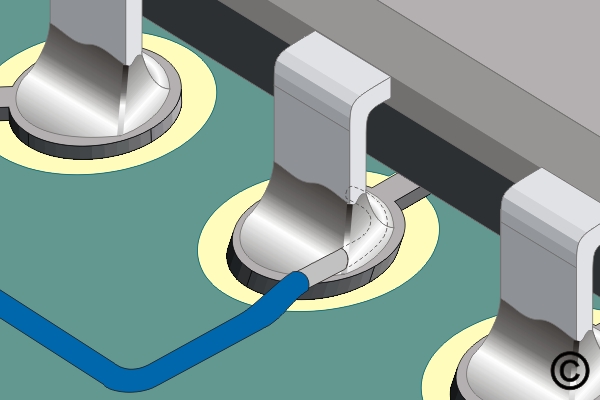

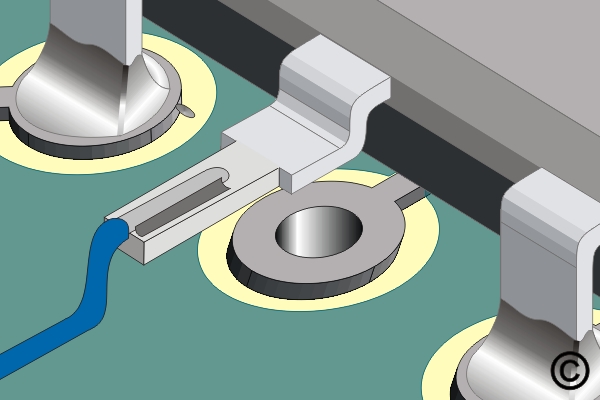

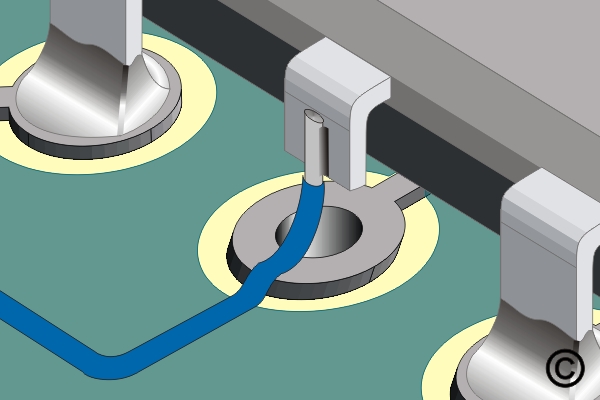

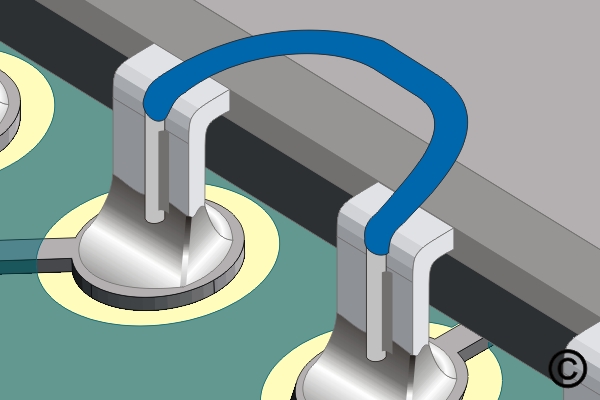

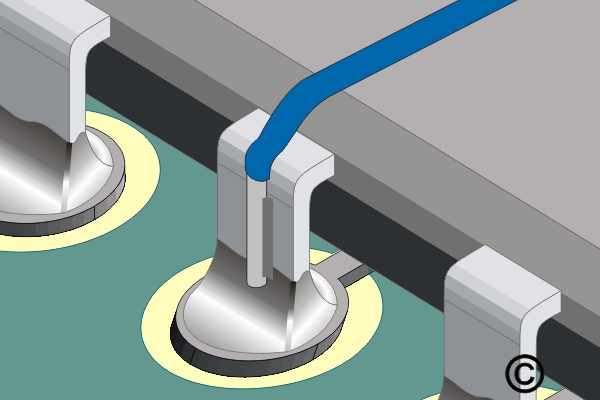

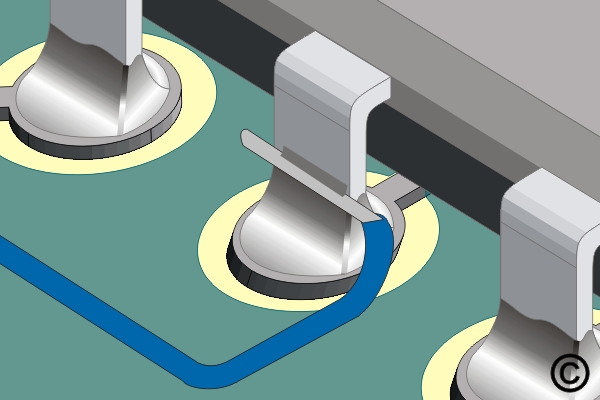

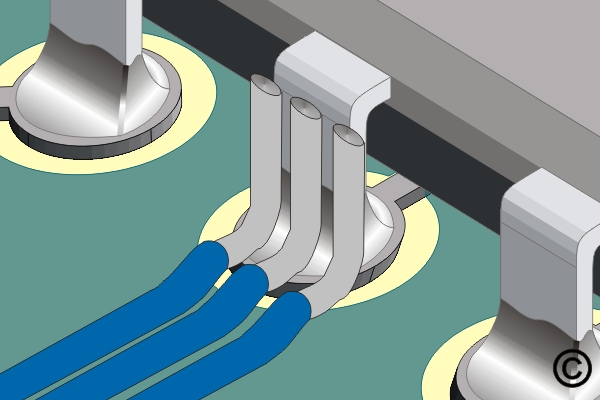

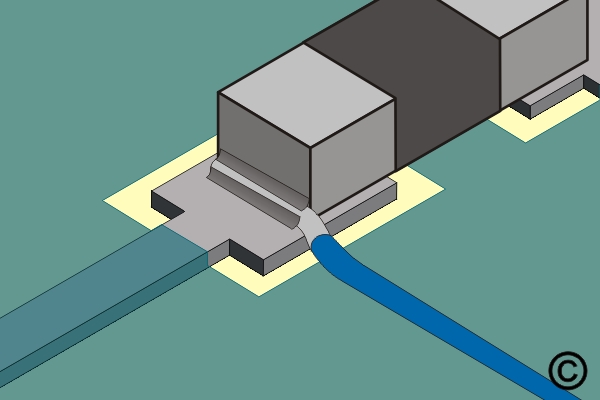

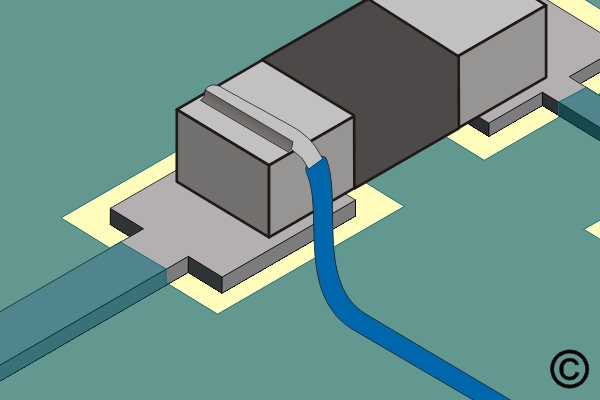

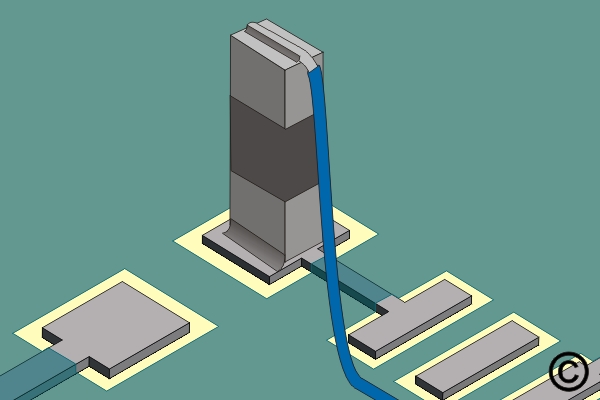

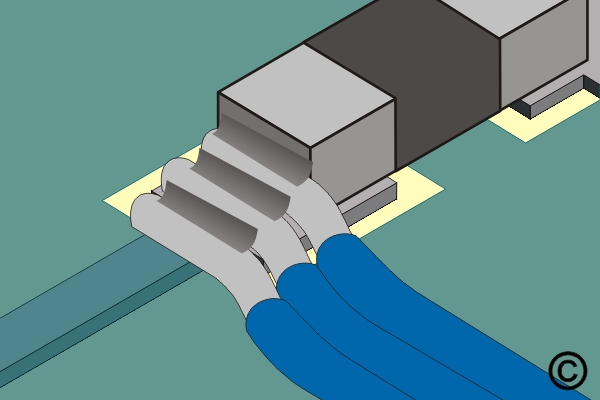

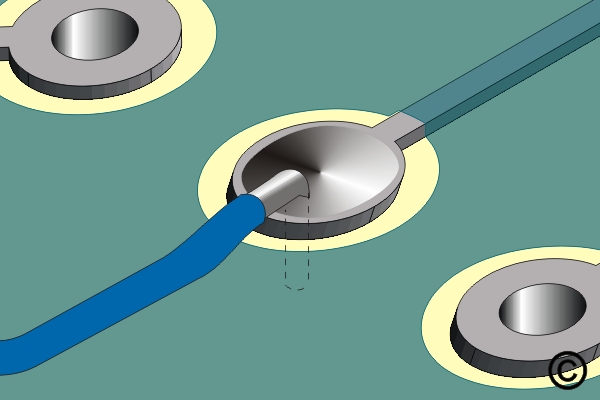

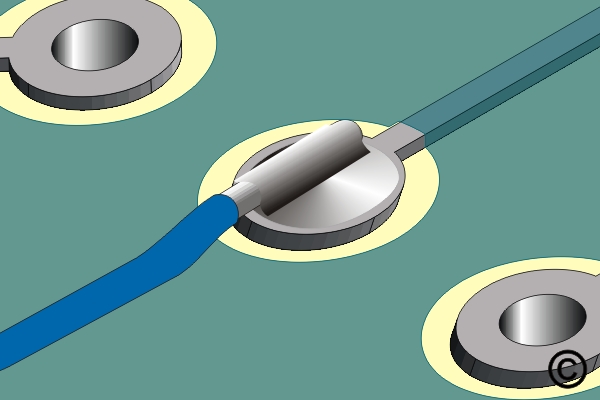

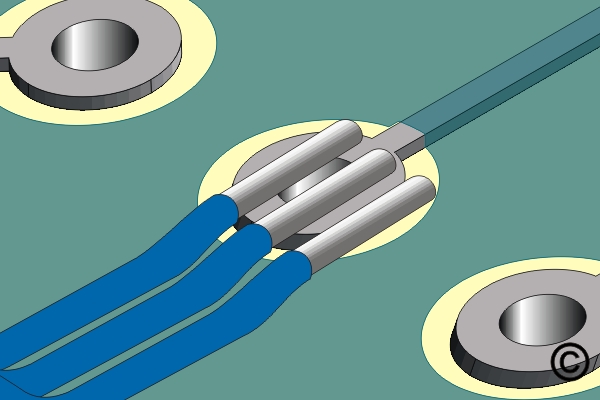

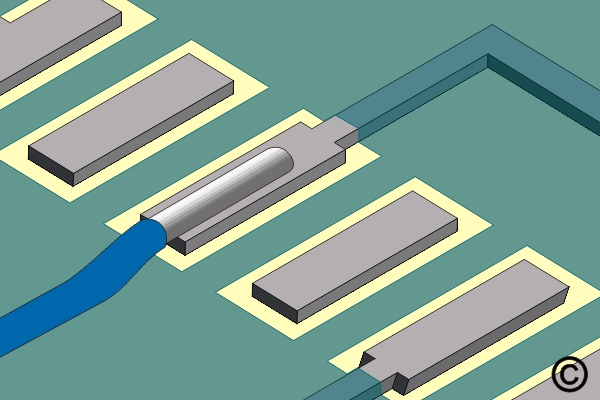

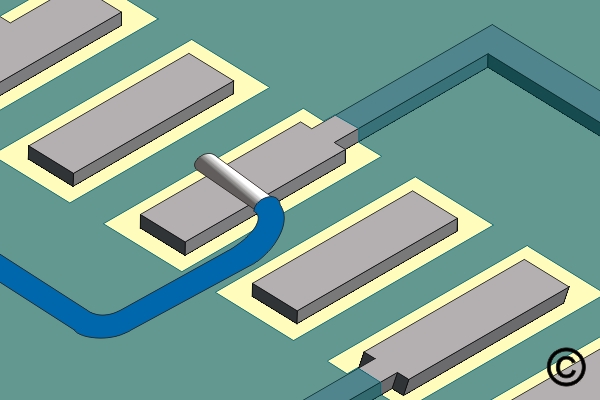

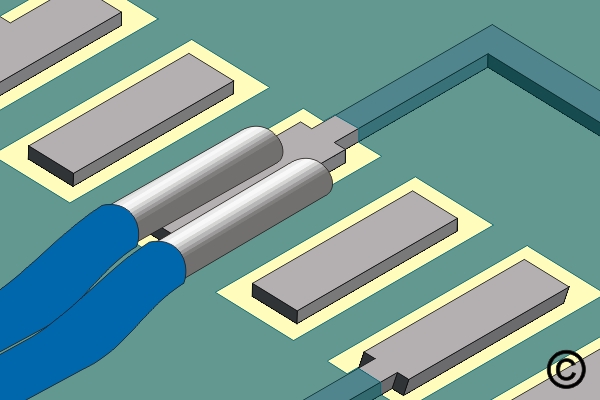

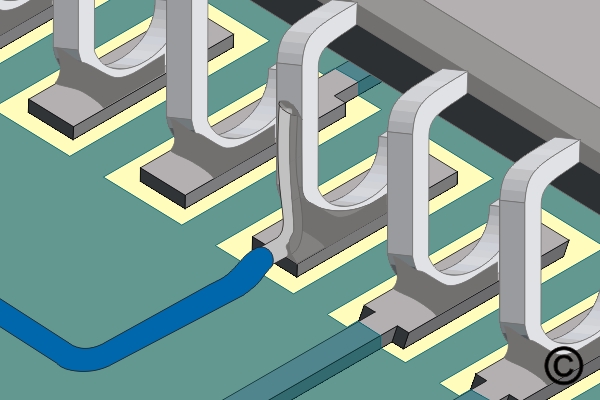

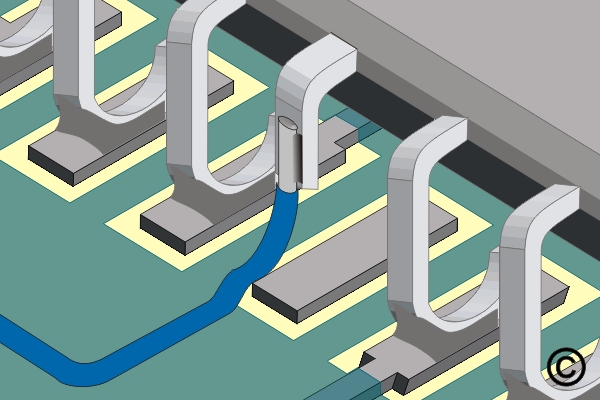

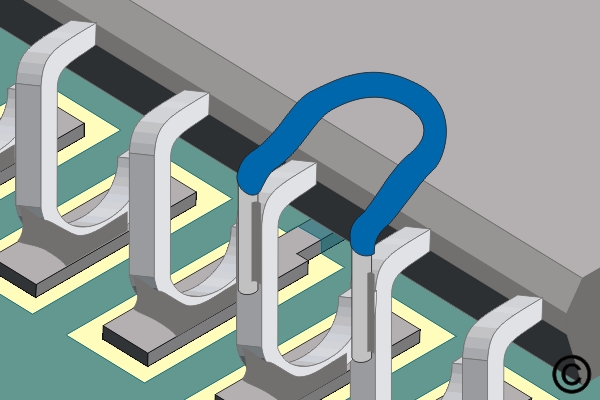

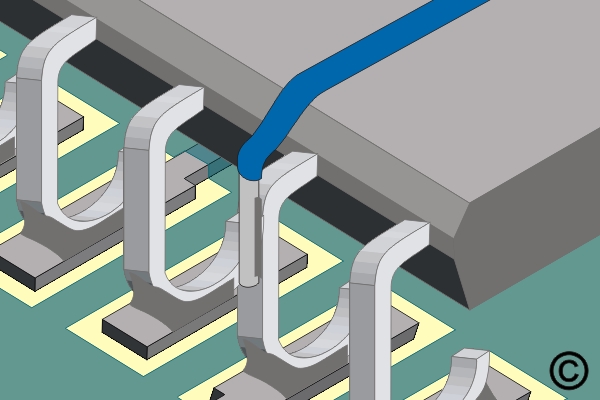

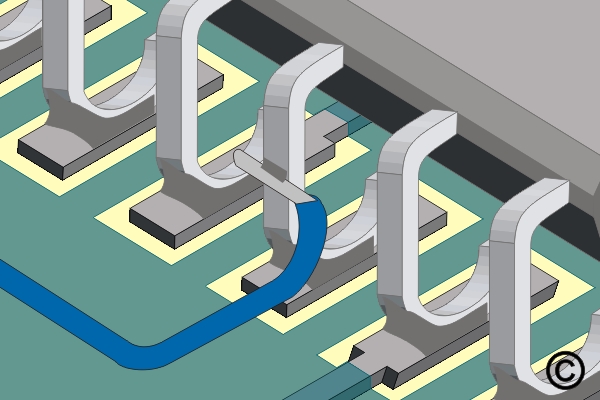

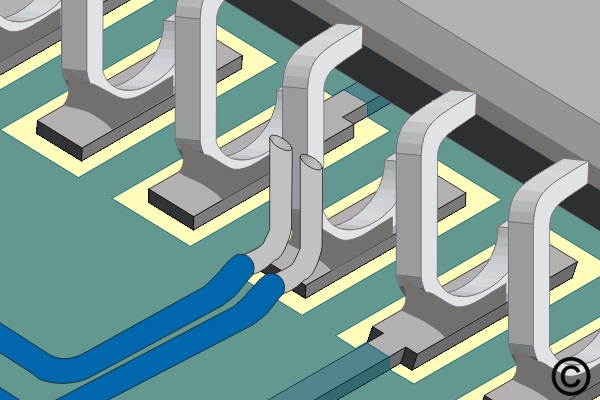

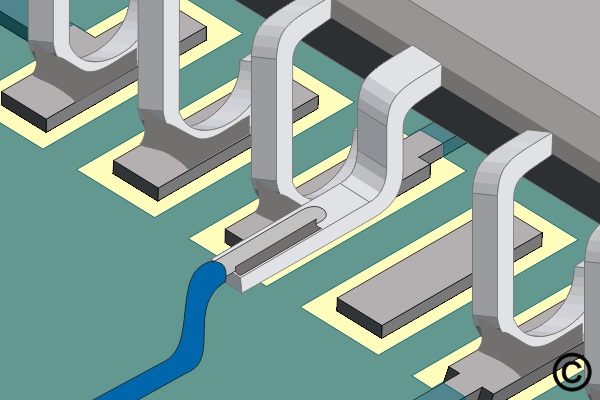

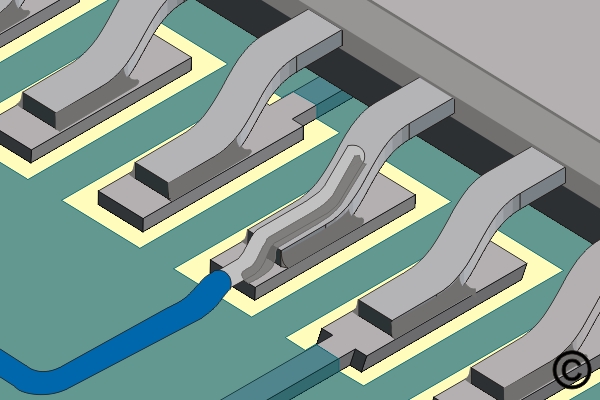

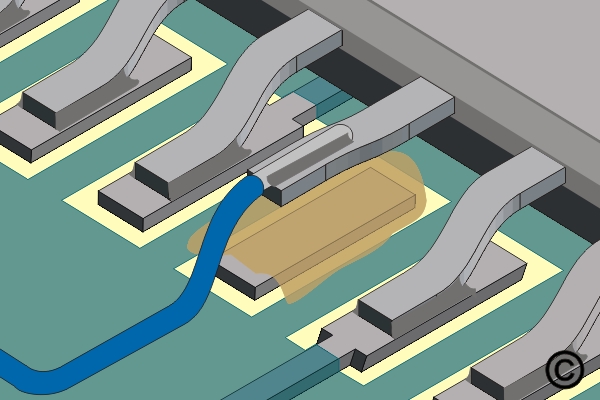

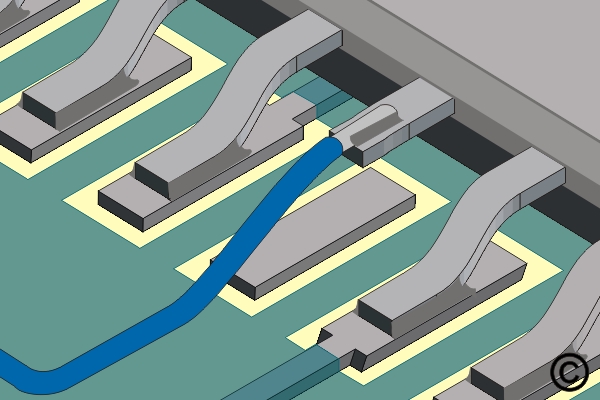

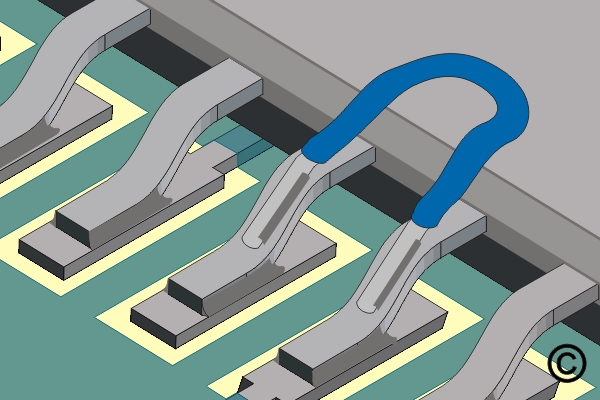

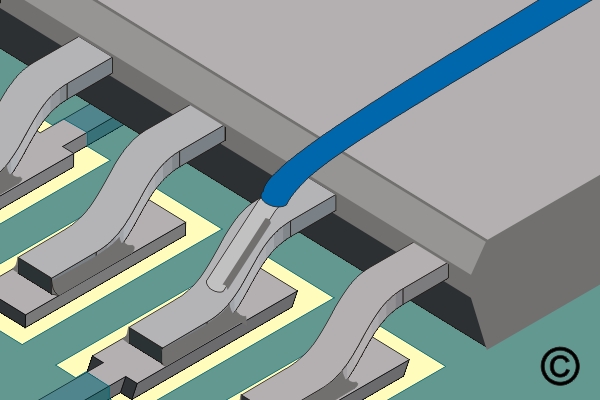

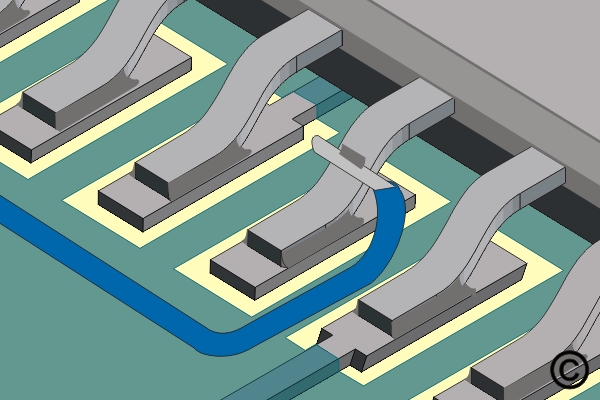

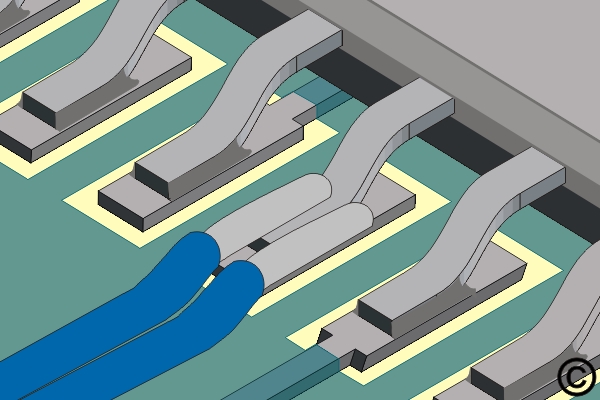

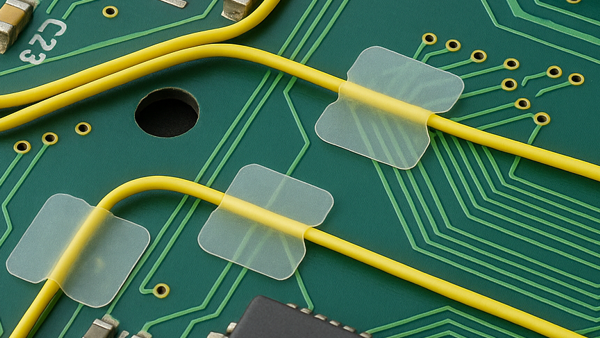

6.1 Jumper Wires

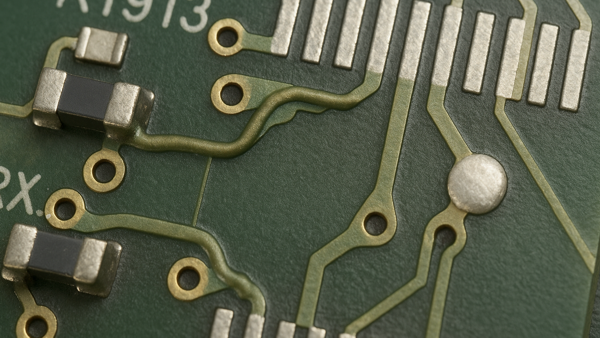

Procedure covers methods for using jumper wires on circuit board assemblies.

Minimum Skill Level: Intermediate

Conformance Level: High

REQUEST FOR QUOTE GUIDES INDEX

Jumper Wires

See the procedure below for detailed instructions.

Wire Dots are a thin, flexible polymer film coated on one side with a high-performance, electronics grade permanent pressure-sensitive adhesive.

LEARN MORE

We're here to help with ECO rework, jumper wire adds, circuit cuts, and various complex modifications.

LEARN MORE

SLIDESHOW STARTING

❮

❯