A Solution for Broken Pin Repair

|

|

|

|

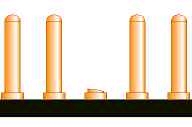

Broken pin on a pin grid array.

|

While working with an extremely expensive pin grid array style component, a customer reported that they broke off a pin at the base near the component body. The shoulder of the pin was approximately twice the diameter of the main pin body and approximately .50" (12.7 mm) in length. Is it possible to repair damage to a component like this?

Any repair would have to endure the mechanical stress of insertion plus the thermal stress of soldering temperatures when the component was soldered back into the circuit board.

Here's the solution. A commercially available pin with the same diameter and gold plating as the original pin but with a larger base was ordered. The key feature was the wide base because the repair required hollowing out the base to fit over the stub of the broken pin remaining on the component body.

|

|

|

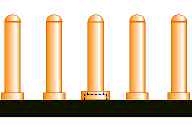

Broken pin repaired by soldering on a specially modified new pin.

|

The center of the pin base was machined to a depth of .050" (1.27 mm), leaving a thin wall around the circumference of the pin base. This machined opening was tinned with high-temperature solder. The stub remaining on the component was also tinned with high-temperature solder.

A support fixture was fabricated by drilling clearance holes in a piece of laminate following the pin pattern. The fixture precisely positioned the replacement pin while it was soldered onto the component using a hot plate, flux, high-temperature solder, and a hot air rework system.

The final step was to add a small bead of high-strength epoxy around the rework area.

Several members of the Circuit Technology Center team contributed to this feature story.

|

|

|

|

|