7.2.1 Soldering Through Hole Components, Point To Point Method

Procedure covers soldering of through hole components using point to point hand soldering.

Minimum Skill Level: Intermediate

Conformance Level: Medium

REQUEST FOR QUOTE GUIDES INDEX

Soldering Through Hole Components, Point To Point Method

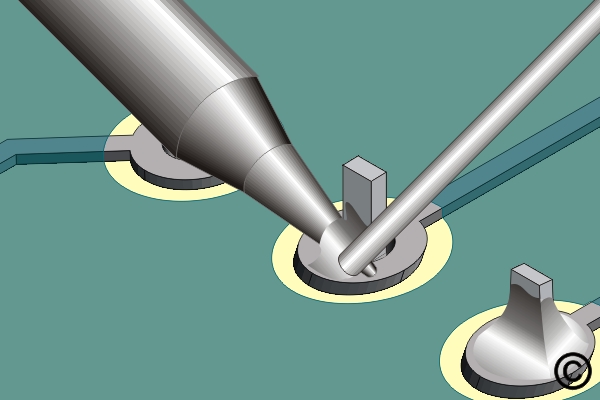

Apply solder at the junction of soldering iron tip and lead to make a solder bridge.

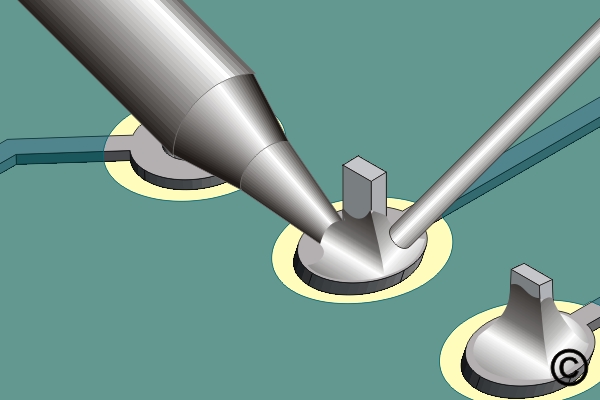

Feed solder into the joint from the side opposite from the iron tip until the proper fillet is achieved.

We're here to help with all your challenging circuit board and electronic component rework and repair needs.

LEARN MORE

SLIDESHOW STARTING

❮

❯