|

Outline

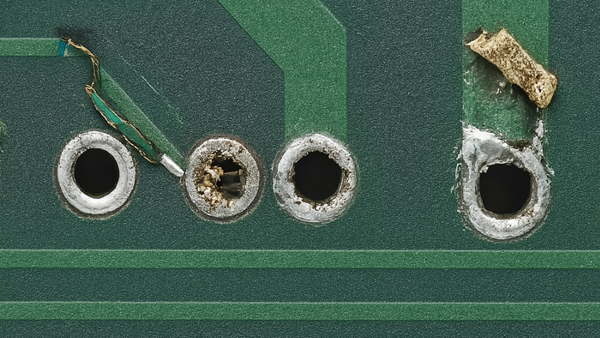

This procedure describes the use of flat set eyelets for the repair of a through connection that has an inner layer connect. No surface wire is used. The inner layer reconnect is established by soldering the barrel of an eyelet to the exposed inner layer, and the connection is encapsulated in high-strength epoxy.

|

||||||||||||||||||||||||||||||||||||||||||

|

Procedure

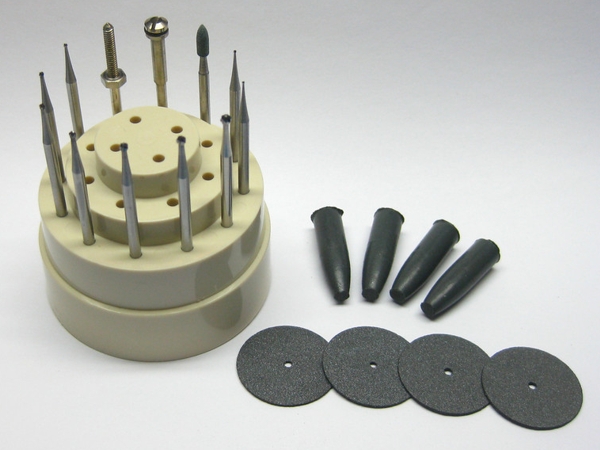

Eyelet Selection Criteria

Evaluation

|

||||||||||||||||||||||||||||||||||||||||||

Images and Figures

Plated Hole Repair, Inner Layer Connection

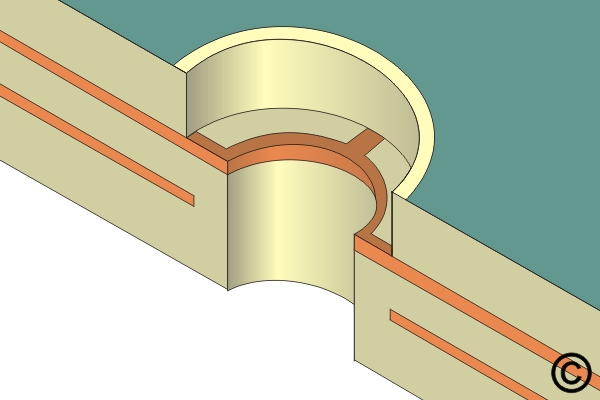

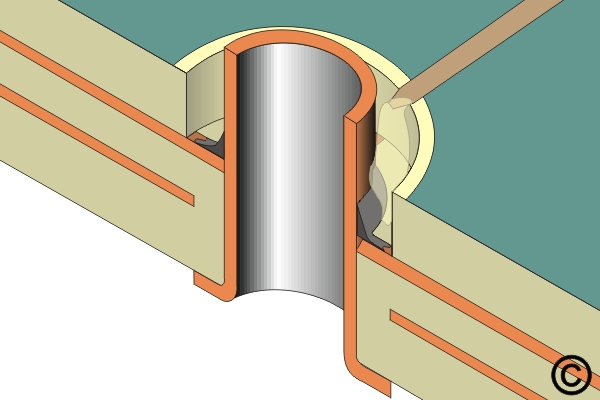

Figure 1. Mill down to and expose inner layer signal or plane.

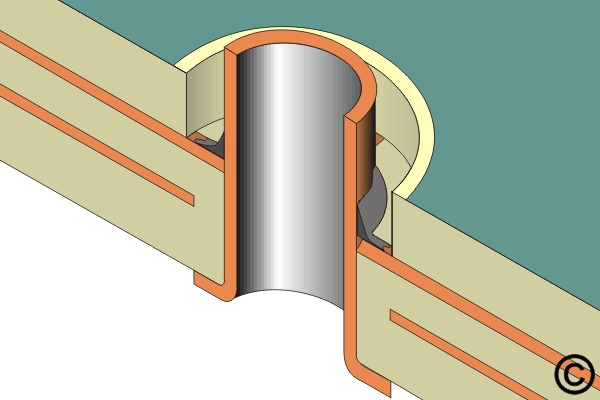

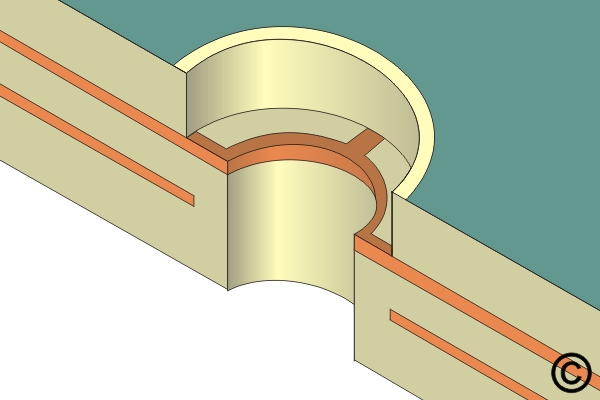

Figure 2. Solder the eyelet barrel to the exposed inner layer signal or plane.

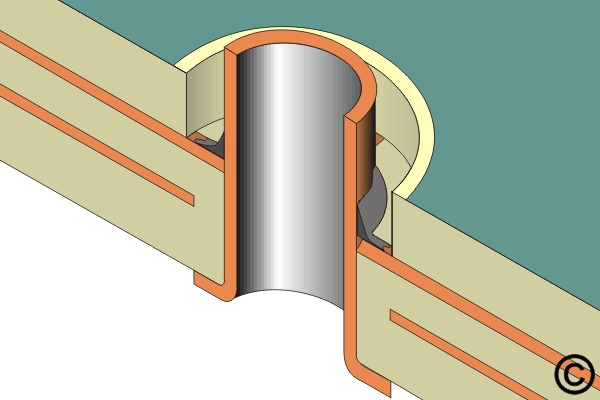

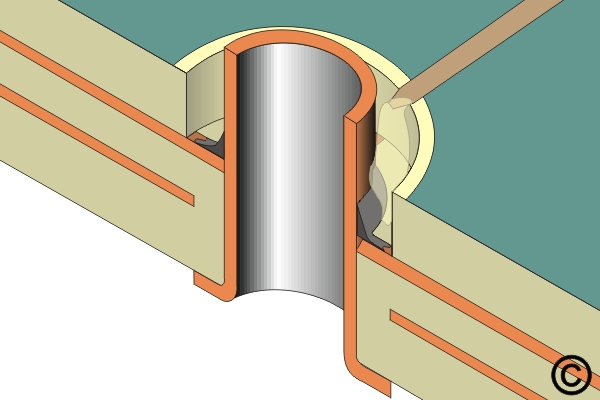

Figure 3. Fill the milled hole with the epoxy up to, and level with, the surface of the board.

|

||||||||||||||||||||||||||||||||||||||||||

5.3 Plated Hole Repair, Inner Layer Connection

Procedure to repair damaged plated holes that have an inner inner layer connection on circuit board assemblies.

Minimum Skill Level: Expert

Conformance Level: Medium

REQUEST FOR QUOTE GUIDES INDEX

Plated Hole Repair, Inner Layer Connection

Mill down to and expose inner layer signal or plane.

Solder the eyelet barrel to the exposed inner layer signal or plane.

Fill the milled hole with the epoxy up to, and level with, the surface of the board.

Eyelets are the most common way to repair plated holes conformint to IPC guidelines.

LEARN MORE

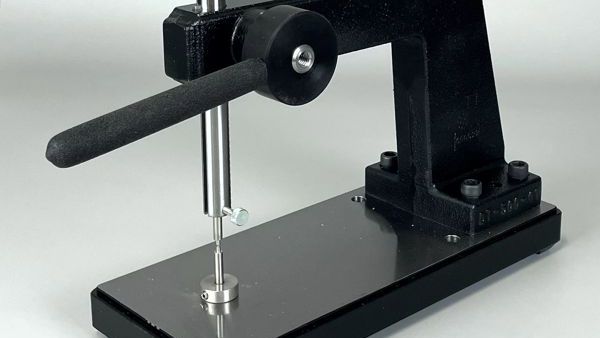

This rugged, heavy-duty press precisely forms eyelets for repair or assembly, ensuring the eyelets meet industry guidelines.

LEARN MORE

We're here to help restore damaged circuitry and plated holes following IPC guidelines.

LEARN MORE

SLIDESHOW STARTING

❮

❯