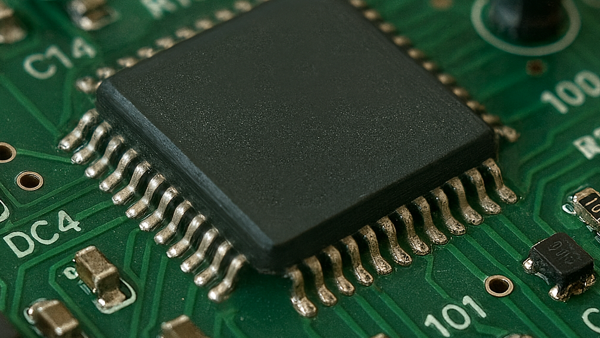

A manufacturer of outdoor electronic billboards had hundreds of circuit board assemblies that were returned from the field. They all required removing and replacing a faulty 44-pin fine pitch QFP device. These 15" x 10" circuit board assemblies were populated with over 1500 surface-mount LEDs and hundreds of other surface-mount devices.

Ordinarily, removing and replacing a QFP would be a relatively straightforward rework project. In this case, however, the boards were encapsulated entirely with a 0.20" thick silicone potting gel, making for a significant challenge. (See Figure 1)

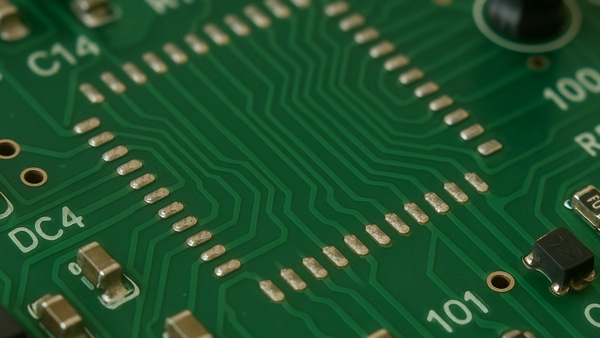

The engineers and technicians at the Circuit Technology Center debated several approaches to remove the potting gel selectively. Ultimately, mechanical removal of the gel was chosen as the safest and most reliable way to proceed.

Highly skilled technicians, with a zoom microscope and using a sharp knife, extracted a 0.45" x 0.59" section of the gel to expose the QFP. (See Figure 2) During this process, great care was taken to prevent damage to the baseboard material and adjacent LED devices. Once the potting gel was removed and the QFP exposed, the boards were sent to the hot gas rework department to remove the defective QFPs. (See Figure 3)

Circuit Technology Center has seven top-line Air-Vac programmable hot gas rework systems. These systems are used for various surface-mount and leadless device removal and replacement procedures, including BGAs, QFNs, LGA, and more. These recipe-driven machines, in the hands of trained operators, ensure a very stable and highly repeatable rework process. Once the defective QFPs were removed, the sites were inspected, cleaned, and prepped for new device placement.

The re-soldering process was more challenging than usual because the component rework site was located in a relatively deep and narrow well within the silicone gel. Circuit Technology Center's most highly skilled soldering technicians were assigned to this final step of the rework process.